Advantages of Semi-automatic Quick-change C purlin machine :

1.Change different purlin size in ten minutes, without changing rollers or spacers.

2.Post-cutting design, no worry about twist and flare caused by Pre-cutting design.

3.With computer controlled system which easy to operate and save time and cost .

4.Post-cutting system or fly-cutting for option.

5.We are the first and only factory to have a whole Baking Finishing Line to treat the spare parts.

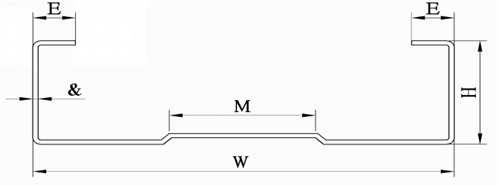

Profile drawing

Product Description

|

Bottom width(W)

|

50-200mm

|

|

Heigh(H)

|

20-60mm

|

|

Small side(E)

|

10-20mm

|

|

Material width(λ)

|

120-360mm

|

|

Material thickness(&)

|

Q235(1.0-2.0mm)/G350(1.0-1.5mm)

|

|

Main shafts diameter

|

φ60mm round steel

|

|

Levelling shaft diameter

|

solid rollers φ80mm(upper2,down3)

|

|

Wall panel thickness

|

18mm

|

|

Machine base size

|

H346*174

|

|

Driving power

|

Motor 7.5KW, Helical gear reducer with K series

|

|

Punching and cutting power

|

Hydraulic power 4.0KW

|

|

Forming speed

|

20m/min without punching

|

|

No. of punching

|

2 sets(double+sigle)14*25

|

|

Punching and cutting mode

|

Pre punching and cutting+ post cutting

|

|

roller material

|

Gcr15

|

|

Forming station

|

3+4+5=12 stations(without embossing)

|

|

Blade material

|

Cr12Mov,Heat treatment after wire cutting

|

|

Control mode

|

PLC(Delta Taiwan)

|

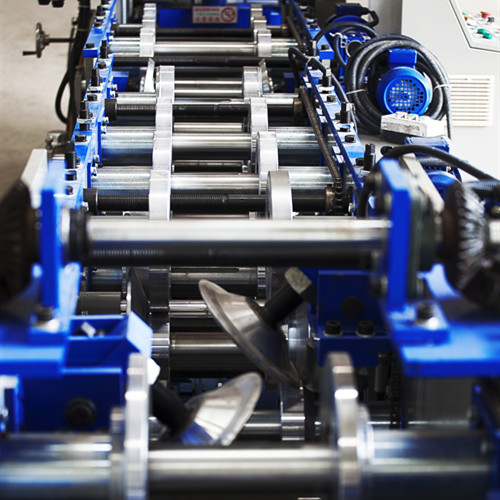

Machine Parts

1. Feeding material guide and leveling device

Two feeding material guide rollers (one up and one down roller) and 5 leveling rollers ( 2 up and 3 down rollers ) for straightening.

solid and shafts diameter=φ78mm

2. Pre-punching system

Each purlin machine has 3 punching devices (one cylinder for single hole and 2 cylinders for dual-holes.)

Also, can make more punching device or not as customer’s requires.

3.C purlin machine rollers and shafts

All purlin machine rollers manufactured from GCr15, precision machined, hard Chrome Coated;

Shafts manufactured from #45 steel or Gcr15 for optional,

Main Shaft Diameter=φ60/45mm, quenching and tempering treated

4. C purlin machine post-cutting system:

Choose our purlin machine ,you don't need to change cutter for different size;

Beside, our purlin machine can changing for height and bottom width unlimited.

Cutting blades made by high quality mold steel Cr12 with heat treatment;

Cutter frame made from high quality 30mm steel plate by welding.

5. Control System

C purlin machine control box

(Touch screen brand: WEINVIEW, Inverter brand: Finland VOCAN/Taiwan DELTA/ALPHA, Encoder brand: Japan Koyo/OMRON)

6. uncoiler

C purlin machine uncoiler

One set manual uncoiler, Un-powered, manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max. 3Ton

7. C purlin exit rack

Un-powered, three units