Advantages of Automatic Quick-change C purlin machine :

1.Automatically change different purlin size in one minute, without changing rollers or spacers.

2.Post-cutting design, no worry about twist and flare caused by Pre-cutting design.

3.With computer controlled system which easy to operate and save time and cost .

4.Post-cutting system or fly-cutting for option.

5.We are the first and only factory to have a whole Baking Finishing Line to treat the spare parts.

Send your drawing to us, we can customize it for you.

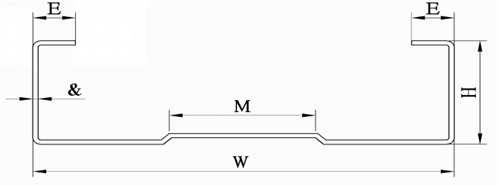

Profile drawing

Product Specification

|

Bottom(W)

|

70-250mm

|

|

Height(H)

|

25-70mm

|

|

Small size(E)

|

10-20mm

|

|

Material width(λ)

|

130-418mm

|

|

Material thickness(&)

|

Q235(1.3-2.5mm)/G350(1.3-2.0mm)

|

|

Chain size

|

1.0 inch +1.2 inch +1.5 inch

|

|

Main shaft diameter

|

φ70/55mm Round steel with modulating treatment

|

|

Leveling shaft diameter

|

Solid rollers φ85mm(upper2, down3)

|

|

Wall panel thickness

|

22mm

|

|

Machine base size

|

H396*199

|

|

Driving power

|

Motor 11.0KW, Helical gear reducer with K series

|

|

Punching and cutting power

|

Hydraulic power 5.5KW

|

|

Forming speed

|

20m/min without punching

|

|

No. of punching

|

2 sets(Double+single)14*25

|

|

Puning and cutting way

|

Pre punching and cutting+ post cutting

|

|

Roller material

|

Gcr15

|

|

Forming station

|

4+4+5=13 station(without embossing)

|

|

Blade material

|

Cr12Mov,Heat treatment after wire cutting

|

|

Control mode

|

PLC(Delta Taiwan)

|

Machine Parts

1.Feeding material guide and leveling device

Each of our purlin machine has a feeding material guide with two rollers (one up and one down roller), and leveling device with 5 rollers ( 2 up and 3 down rollers ) for straightening.

solid and shafts diameter=φ85mm

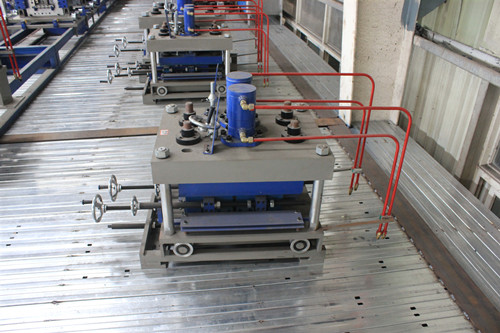

2. Pre-punching system

Hydraulic punching device with 3 cylinders (one cylinder for single hole and 2 cylinders for dual-holes.)

Also, can make more punching sets as customer’s requires.

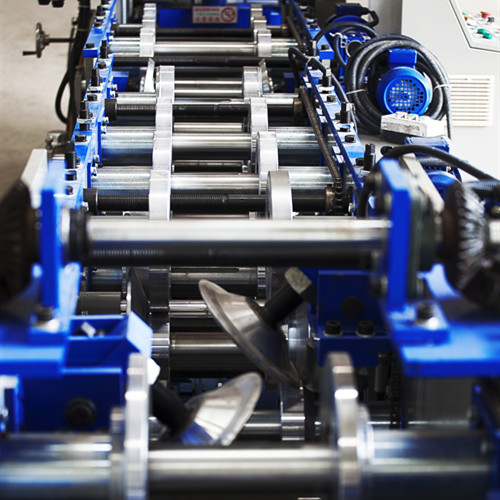

3. C purlin machine rollers and shafts

Purlin machine rollers manufactured from bearing steel GCr15, precision machined, hard Chrome Coated;

All purlin machine shafts manufactured from #45 steel or Gcr15 for optional,

Main Shaft Diameter=φ80/65mm, quenching and tempering treated

4.C purlin machine post-cutting system:

You don't need to change cutter for different size;

Further more, you can changing purlin height and bottom width unlimited.

Cutting blades made by high quality mold steel Cr12 with heat treatment.

Cutter frame made from high quality 30mm steel plate by welding.

5. Control System

C purlin machine control box

(Touch screen brand: WEINVIEW, Inverter brand: Finland VOCAN/Taiwan DELTA/ALPHA, Encoder brand: Japan Koyo/OMRON)

6. Uncoiler

C purlin machine uncoiler

One set manual uncoiler, Un-powered, manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max. 3Ton

With hydra uncoiler for your option

7. C purlin exit rack

Un-powered, three units