-

Core Structure & Key Properties

- Structure Composition: Ceramic tube (alumina/zirconia material) + heating coil + lead wire + insulation layer.

- Critical Performance Traits:

- Rapid heating & high efficiency: Fast thermal response, heat conversion rate up to 90%+, saves energy consumption.

- Wide temperature range: Operating temperature 200–1200℃ (special formulations up to 1600℃), adaptable to diverse heating needs.

- Excellent corrosion/oxidation resistance: Ceramic tube resists high-temperature oxidation and corrosive gas erosion.

- Safe & stable: Insulating ceramic shell prevents electric leakage, stable performance under long-term operation.

- Compact design: Small volume, easy to install in limited spaces, suitable for localized heating.

Typical Applications

- Industrial manufacturing: Plastic molding, metal heat treatment, glass processing, and semiconductor wafer heating.

- Commercial & household: Small appliances (electric stoves, toasters), laboratory equipment, and food drying machines.

- Special environments: High-temperature ovens, kilns, and corrosive industrial workshops (chemical, electroplating industries).

- Agricultural use: Greenhouse heating, seedling cultivation temperature control.

Customization & Technical Specifications

- Size options: Diameter 6–25mm, length 50–1500mm (customizable for special requirements).

- Power range: 50W–2000W, single-ended or double-ended wiring designs.

- Ceramic tube material: High-purity alumina (cost-effective, for ≤1200℃) or zirconia (high-temperature resistant, for ≥1200℃).

- Additional features: Optional temperature sensors, waterproof coatings, or anti-corrosion surface treatments.

Technical Parameters

| Item |

Unit |

Zirconia ceramic |

99% alumina ceramic |

96% alumina ceramic |

95% alumina ceramic |

Steatite ceramic |

Mullite ceramic |

Cordierite ceramic |

| Bulk density |

g/cm3 |

6 |

3.8 |

3.7 |

3.6 |

2.8 |

2.2 |

2.3 |

| Water absorption |

% |

0 |

0 |

0 |

0 |

0 |

12 |

12 |

| Thermal Conductivity |

(w/m.k) |

10 |

19-30 |

16-28 |

14-24 |

2-3 |

2-6 |

1.3-1.8 |

| Resistance to thermal shock,Minimum |

TK? |

70 |

150 |

140 |

140 |

80 |

150 |

300 |

| Withstand voltage,Minimum |

KV |

15 |

20 |

18 |

18 |

20 |

25 |

- |

| Flexural strength |

Mpa |

1000 |

300 |

280 |

240 |

120 |

120 |

30 |

| Sintering temperature |

℃ |

1500 |

1670 |

1600 |

1600 |

1250 |

1250 |

1250 |

| Maximum working temperature |

℃ |

1200 |

1500 |

1200 |

1200 |

800 |

1000 |

1000 |

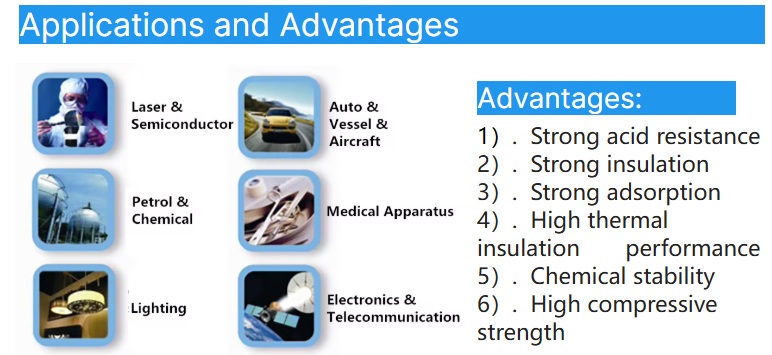

Application

Specifically used for high-temperature and high-voltage insulation parts, circuit substrates, high-temperature devices, etc. As the main representative of precision ceramic materials, it is widely used in industries such as semiconductors, petrochemicals, and electronics.

Advantages

1. we support OEM and ODM;

2. We have a professional R&D team and technical support;

3. We provide real-time logistics update information;

4. We support 24-hour online service;

5. We support T/T,L/c payment;

6. We have a professional QC team to check the quality before delivery.

Certificate

FAQ

1. How can you get quotation?

Please kindly send me your drawing with technic requirement and demand quantity.

If you don't have the drawing, please kindly courier samples to us. we will quote our best price in 24 hours.

2. How can you get samples?

We can supply free samples if we have them in stock. If we haven't produce the products, we can supply some free samples after getting tool fee. Please take note that the courier fee should be at destination.

3. What’s the lead-time for samples and batch orders?

It is 18days for supplying samples. It is around 25days for batch orders.

4. Can I visit you?

Sure. If you're a volume buyer and would like to visit our in-house products and production line, please contact us to make an appointment.