Single Side Automatic CNC Spot Welding Machine Welder With 5000A / 8000A Inverter DC Welding Power Supply / Transistor Welding Power Supply

Introduction

Full automatic single-sided spot welding has strong flexibility. The machine head is driven by the cylinder for spot welding, with stable performance. It is suitable for the processing of various and diversified battery packs.

The fixture replacement is convenient and fast, the appearance is atmospheric and beautiful, and the all aluminum alloy body. There are two shapes for customers to choose from: one is the open fuselage without cover, which is more convenient for users; One is the fuselage with cover, translucent acrylic cover, high-end and high-grade, with stronger integrity, making the welding environment more quiet and comfortable.

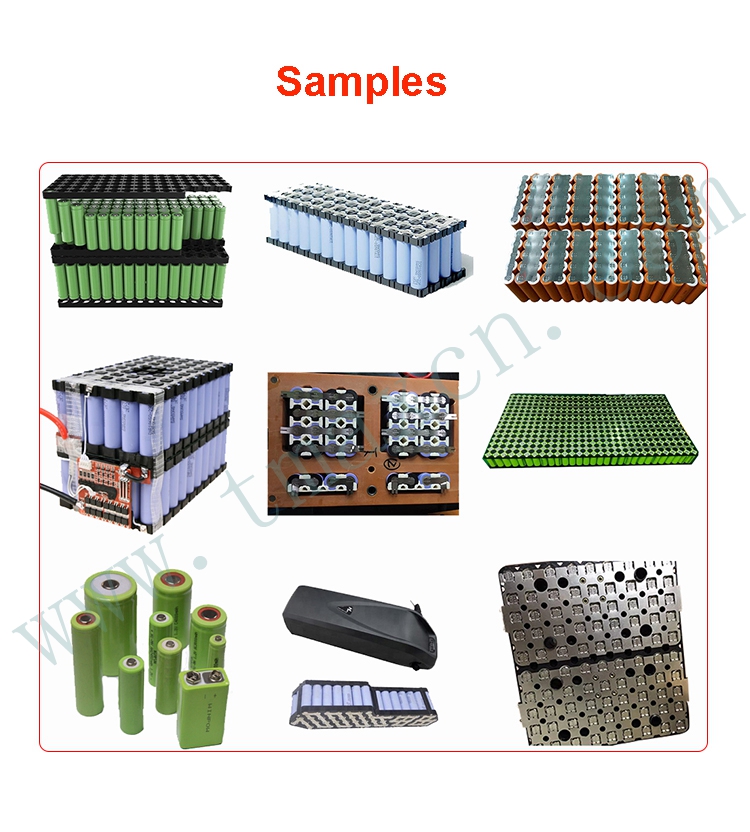

Application:

Photovoltaic, power battery, NiMH lithium battery and other batteries are connected with nickel alloy strip, aluminum nickel composite strip, wire and guide strip, household electrical parts and guide strip, hardware accessories, copper and silver products, stainless steel peripheral connection, bulb foot welding, electronic parts, all kinds of high and low conductive metal welding, etc.

Feature:

1) Induct the load voltage, control the voltage in the feedback mode, and realize high-quality welding.

2) Power on mode of pre heat and main heat: preheat before welding to ensure stable welding quality.

3) Keep the continuity of energy density, short welding time, reduce the deformation and discoloration of base metal. (the welding time is controlled in microseconds, and the mode of continuous output)

4) Easy to change from low current to high current, suitable for precision welding.

5) The upper and lower limits of current can be set to judge whether the welding quality is good or not, which is suitable for the welding automation platform.

6) The welding current will rise with the power on time to ensure the welding effect.

7) Stable control system

8) High configuration regulating device

9) High precision working procedure

10) High cost performance of products

Performance Characteristics

1. Touch screen display, more convenient operation and clearer display.

2. Three file programming modes, including manual input, array and CAD pattern import, can easily and quickly deal with various complex program editing.

3. The welding head has the function of air cooling or water cooling, which can effectively reduce the impact of the temperature of the spot welding needle on the welding quality.

4. It can store up to 99 groups of files, which is simple to call and does not need complex line change and machine adjustment process.

5. The spot welding procedure of side a and side B of the fixture can be switched.

Basic Parameters

|

X-axis Travel

|

500mm

|

|

Y-axis Travel

|

400mm

|

|

Spot Welding Speed

|

0.35s/point;2800pcs/h

|

|

Maximum Speed of Motor Drive

|

1000mm/s

|

|

Maximum Number of Loaded Cells

|

26 in X Direction and 26 in Y Direction

(Standard 18650 Lithium Cell)

|

|

Number of File Groups that can be Saved

|

999 Group

|

|

Operating System

|

Embedded System + Man-Machine Screen

|

|

Transmission Mode

|

Stepping + Imported Precision Linear Guide Rail (Optional Servo + Screw)

|

|

Equipment Power Supply

|

Single Phase ~ 220V + 10% / 50Hz ±10%

|

|

Equipment Air Pressure

|

0.4~0. 7Mpa

|

|

Equipment Weight

|

200 KG

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.