Single Tube Clear NIR Halogen Lamps for Semiconductor Rapid Thermal Processing

Quick details

| Parameters |

single tube infrared heater lamps |

| Tube Diameter(mm) |

10 |

10.5 |

11 |

12 |

13 |

13.5 |

15 |

18 |

| Overall Length(mm) |

80-1700 |

80-1700 |

80-1700 |

80-1700 |

80-1700 |

80-2100 |

80-2500 |

80-3000 |

| Tube Thickness(mm) |

1.3 |

1.3 |

1.3 |

1.3-1.5 |

1.5 |

1.5-1.75 |

1.8 |

2.0 |

| Heated Length(mm) |

30-1650 |

30-1650 |

30-1650 |

30-1650 |

30-1650 |

30-2050 |

30-2450 |

30-2950 |

| Max Power(w/cm) |

100 |

100 |

100 |

100 |

100 |

100 |

120 |

150 |

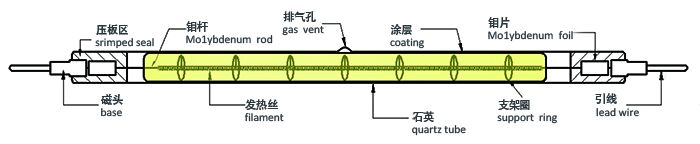

Construction Of single tube short wave IR heating lamps

Short wave quartz infrared heaters are used in various industrial applications. It contains tungsten filament, helically wound, encased in quartz envelope. Tungsten as resistive element is capable of generating temperature in excess of 2750℃. Its response time is very rapid in 1 second it emits over 90% of IR energy. It is by products free & pollution free. Heat focus is very accurate due to compact and narrow diameter of IR tubes. Short wave IR heting element has maximum heating rate of 150w/cm.

Application

Semi Conductor Industries - Heating of wafers

PET preform heating in Stretch blow moulding machines

Powder coating curing

Resins Hardening, Rubber coating drying

Adhesives - End polymerization

Food - Pasteurization / Sterilization

Paper Industry - Humidity Control

Industrial Drying - Paint , Varnishes , Dyeing

Printing - Printing ink drying in screen and offset machines

Plastic welding

Drying of Water-Repellent Coating on Fabric

Textile Embossing and Laminating

Advantages

· Short heating times with maximum efficiency

· High operational reliability

· Optimum customization options and controllability

· Long average lifespan

· Immediately full heat output

· Space-saving, maintenance-friendly installation

· Impressive reliability

· Low running costs

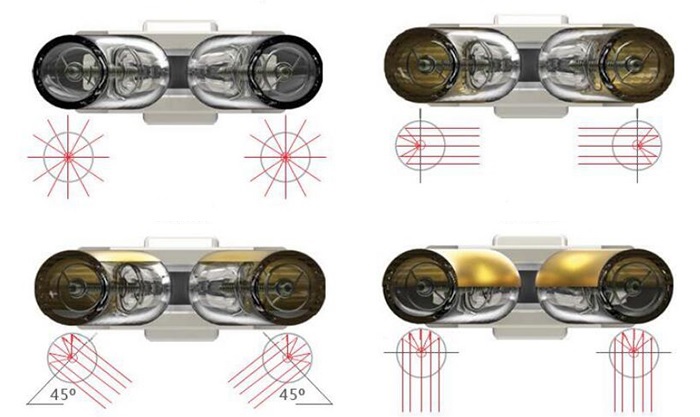

· Also with reflector for directed heat radiation

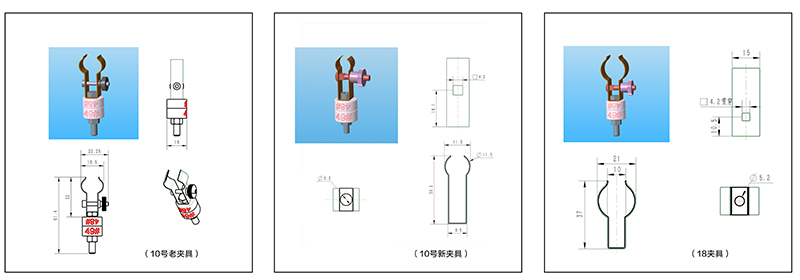

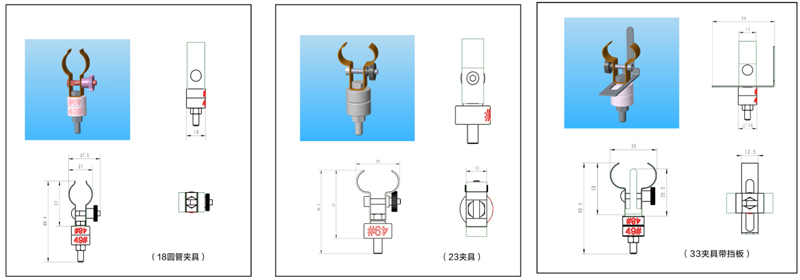

We also provide clips for lamps installing

Why QUICKLY ?

- The materials used for our lamps are at good quality approval UL testing

- As a manufacturer of infrared lamps over 10 years history, and we have experienced workers, half of them have worked for us over 5 years

- We are factory, so we can control the delivery date, material, quality directly

- For any exclusive-human damage within warranty time, we will delivery the replacements within 3-5 work days once confirming

- Safe package to protect lamps from being broken during shipping

- we will provide you the lamp’s holder free of charge ( 2 units clamps for 1 piece lamp)

- Various Payment methods like wire transfer, paypal, western union

- Shipping ways provided including DHL, Fedex, TNT, UPS, air, sea

FAQ

- how to place the order?

Let us know your required lamp specifications including lamp type,diameter, length, power, voltage,reflector...then we send you the

quotation,after payment,production will be started, after finished, they will be shipped to your side.

- Why Quartz Glass as the one main of material?

The choice of quartz glass is not a coincidence: this extraordinary material is totally transparent at IR radiation, can withstand constant

working temperatures of more than 1000°C and it is resistant to chemical corrosion.

- could you supply clamps for lamp installing ?

Yes, we will provide mounting clamps for clients, and the corresponding clamps quantity with purchased lamps are supplied freely bu us.

- Have an unusual design?

Send us a drawing, sketch, or sample and we'll be happy to quote it.

We specialize in small runs and custom designs, but can be highly competitive on large orders as well.

- How does your factory do quality control

" quality is priority", we always and keep paying more attention to QC from the material purchasing to the lamps' packing. Our product have gained CE, ROHS, ISO9001.

- why coating on quartz tube surface ?

QUICKLY offers infrared emitters which coated with gold and white reflector , they can emit heat directly to the product. A gold or white coating on the infrared emitters reflects the infrared radiation. Consequently the infrared radiation impinging on the product is virtually doubled, increasing the effectiveness of the heat output. The reflection efficiency of gold coating is higher than white coating, while for the emitters with high watt density or the surface temperature of the tube above 800°C , we suggest to use ceramic coating as reflector because the temperature resistance is up to 1000°C . In addition to 180° (half-tube) coating, we also manufacture 270° coating or other customer specified degrees.