Single Tube Infrared Heating Tube IR Emitters for Industrial Oven

The economical and powerful single tube shortwave IR heaters are suited for situations requiring high temperatures in the shortest possible time. And because these NIR lamps are also manufactured in special designs, matching the right heater to your application is a snap. When a coating applied on the quartz tube, the IR emitters can operate at a significantly higher efficiency than clear tube IR lamps.

Benefits and features

Long average lifespan: 5000h on average..

High speed: within a second to switch on, short heating times with maximum efficiency

High efficiency: Immediately full heat output

High power density: up to 110 W / cm

High controllability: neither ballast nor special circuits are necessary for basic usage

No air draughts: because of radiation (the same as solar energy)

Clean and odorless: no risk of contamination over environment or target object to be heated.

Extensive assortment: types of voltage, wattage, length, base, wire-harnesses and horizontal or universal operation position are available.

Flexible: Optimum customization options and controllability

High operational reliability: Space-saving, maintenance-friendly installation,low running costs

Also with reflector for directed heat radiation

Quick details

| Parameters |

single tube infrared heater lamps |

| Tube Diameter(mm) |

10 |

10.5 |

11 |

12 |

13 |

13.5 |

15 |

18 |

| Overall Length(mm) |

80-1700 |

80-1700 |

80-1700 |

80-1700 |

80-1700 |

80-2100 |

80-2500 |

80-3000 |

| Tube Thickness(mm) |

1.3 |

1.3 |

1.3 |

1.3-1.5 |

1.5 |

1.5-1.75 |

1.8 |

2.0 |

| Heated Length(mm) |

30-1650 |

30-1650 |

30-1650 |

30-1650 |

30-1650 |

30-2050 |

30-2450 |

30-2950 |

| Max Power(w/cm) |

100 |

100 |

100 |

100 |

100 |

100 |

120 |

150 |

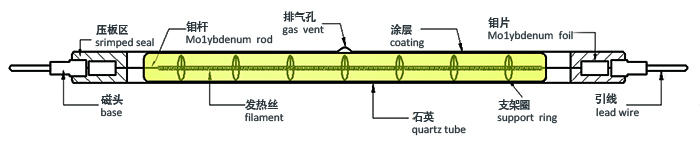

Construction Of single tube short wave IR heating lamps

Short wave quartz infrared heaters are used in various industrial applications. It contains tungsten filament, helically wound, encased in quartz envelope. Tungsten as resistive element is capable of generating temperature in excess of 2750℃. Its response time is very rapid in 1 second it emits over 90% of IR energy. It is by products free & pollution free. Heat focus is very accurate due to compact and narrow diameter of IR tubes. Short wave IR element has maximum heating rate of 150w/cm.

Data for some of single tube IR heaters

| No. |

Volt(V) |

Watt (W) |

OAL (mm) |

HL (mm) |

Tube (mm) |

Reflector |

Warranty |

Posiation |

| 1 |

230 |

1100 |

225 |

150 |

10 |

white |

5000 |

horizontal |

| 2 |

230 |

1500 |

626 |

560 |

10 |

gold |

5000 |

horizontal |

| 3 |

400 |

2500 |

380 |

320 |

10 |

gold |

5000 |

horizontal |

| 4 |

400 |

3000 |

380 |

320 |

10 |

white |

5000 |

horizontal |

| 5 |

240 |

500 |

216 |

150 |

10 |

clear |

5000 |

horizontal |

| 6 |

440 |

1000 |

354 |

280 |

10 |

white |

5000 |

horizontal |

| 7 |

144 |

1200 |

222 |

157 |

10 |

white |

5000 |

horizontal |

| 8 |

144 |

1600 |

222 |

157 |

10 |

clear |

5000 |

horizontal |

| 9 |

400 |

2500 |

354 |

285 |

10 |

gold |

5000 |

horizontal |

| 10 |

400 |

3000 |

354 |

285 |

10 |

gold |

5000 |

horizontal |

| 11 |

235 |

2000 |

353 |

285 |

10 |

white |

5000 |

horizontal |

| 12 |

230 |

2000 |

650 |

505 |

10 |

clear |

5000 |

horizontal |

| 13 |

235 |

30000 |

353 |

280 |

10 |

white |

5000 |

horizontal |

| 14 |

235 |

3000 |

787.5 |

705 |

10 |

clear |

5000 |

horizontal |

| 15 |

144 |

1600 |

225 |

155 |

10 |

white |

5000 |

horizontal |

| 16 |

235 |

2500 |

353 |

285 |

10 |

white |

5000 |

horizontal |

| 17 |

240 |

2000 |

353 |

270 |

10 |

white |

5000 |

horizontal |

| 18 |

400 |

1000 |

352 |

283 |

10 |

clear |

5000 |

horizontal |

| 19 |

400 |

2000 |

352 |

283 |

10 |

gold |

5000 |

horizontal |

| 20 |

220 |

1500 |

440 |

355 |

10 |

gold |

5000 |

horizontal |

| 21 |

220 |

2000 |

275 |

210 |

10 |

white |

5000 |

horizontal |

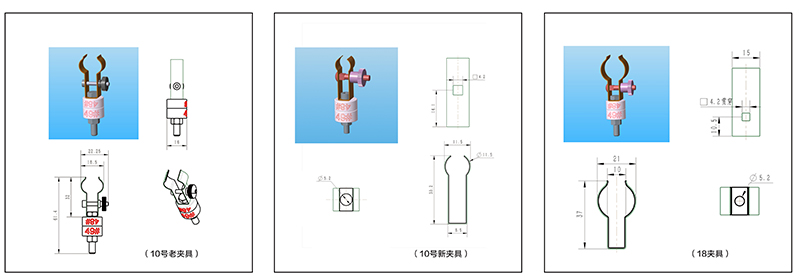

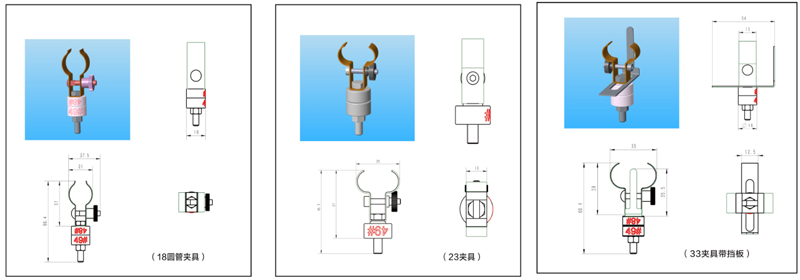

We also provide clips for lamps installing

Application

PET preform heating in Stretch blow moulding machines

Powder coating curing

Resins Hardening, Rubber coating drying

Adhesives - End polymerization

Food - Pasteurization / Sterilization

Paper Industry - Humidity Control

Industrial Drying - Paint , Varnishes , Dyeing

Semi Conductor Industries - Heating of wafers

Printing - Printing ink drying in screen and offset machines

Plastic welding

Drying of Water-Repellent Coating on Fabric

Textile Embossing and Laminating

FAQ

1. how to place the order?

Let us know your required lamp specifications including lamp type,diameter, length, power, voltage,reflector...then we send you the

quotation,after payment,production will be started, after finished, they will be shipped to your side.

2. What is the payment term?

prepayment 100% advance via wire transfer, Paypal, Western Union

3. could you supply clamps for lamp installing ?

Yes, we will provide mounting clamps for clients, and the corresponding clamps quantity with purchased lamps are supplied freely bu us.

4. Have an unusual design?

Send us a drawing, sketch, or sample and we'll be happy to quote it.

We specialize in small runs and custom designs, but can be highly competitive on large orders as well.

5. How does your factory do quality control

" quality is priority", we always and keep paying more attention to QC from the material purchasing to the lamps' packing. Our product have gained CE, ROHS, ISO9001.