Starch is one of the most important raw materials on paper making. It includes Corn (maize) starch, tapioca starch, potato starch and wheat starch. The primary function of starch is increase dry strength and surface improvement of paper.

As a wet end additives, starch increases paper strength and stiffness .

As a surface sizing agent, it improves appearance and feasibility, restrains ink penetration, forms firm surface (which is suitable for better writing and printing) and also prepares the paper sheet for subsequent coating.

As a coating agent, it enhances print-ability and gives a glossy and a fine surface of the paper.

Besides, starch also can reduce cost of paper making.

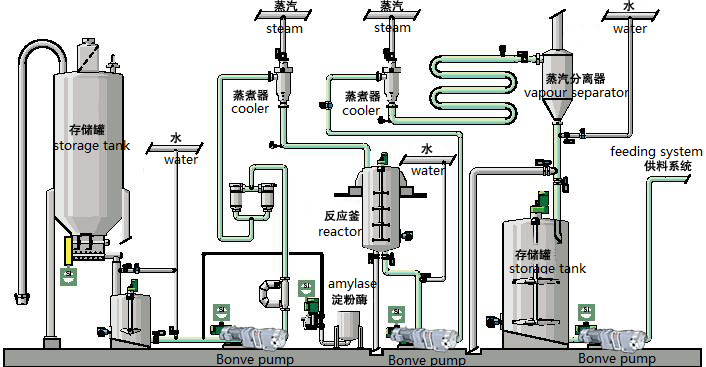

During production, Bonve Lobe Pumps play an important role to transfer starch in the process. Below is a charm to show pump's working.

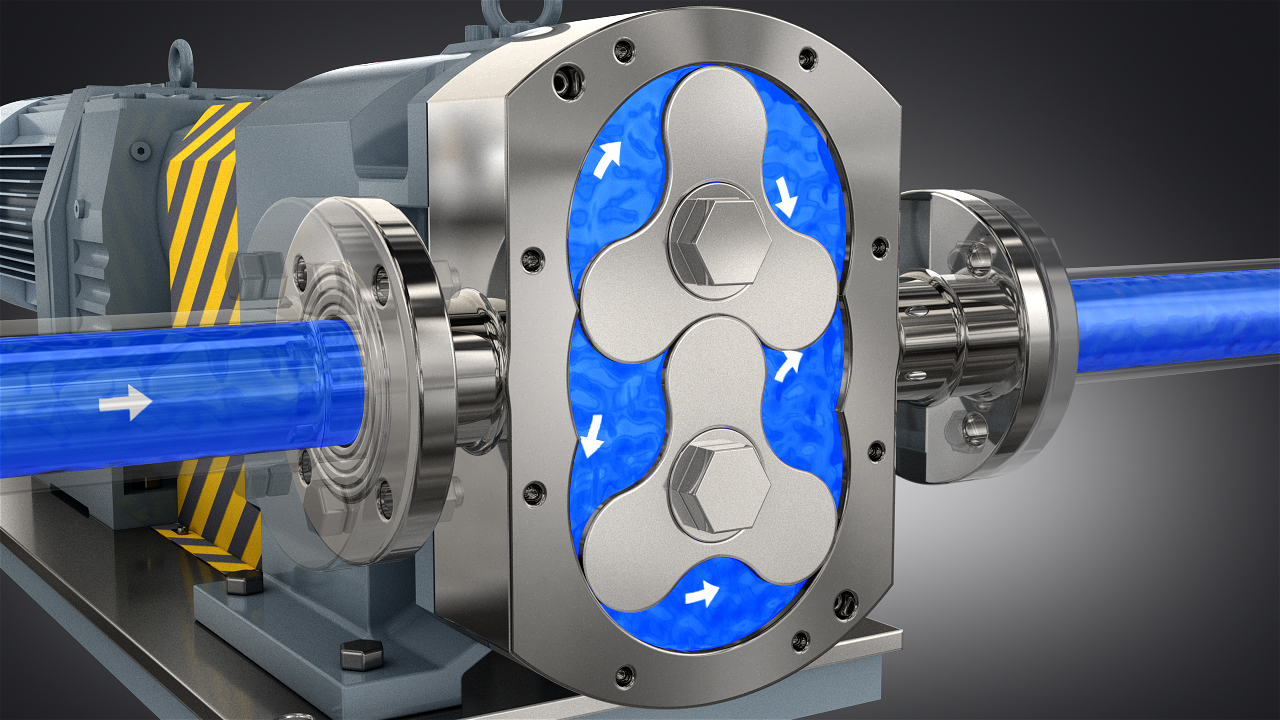

Pump working principle

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

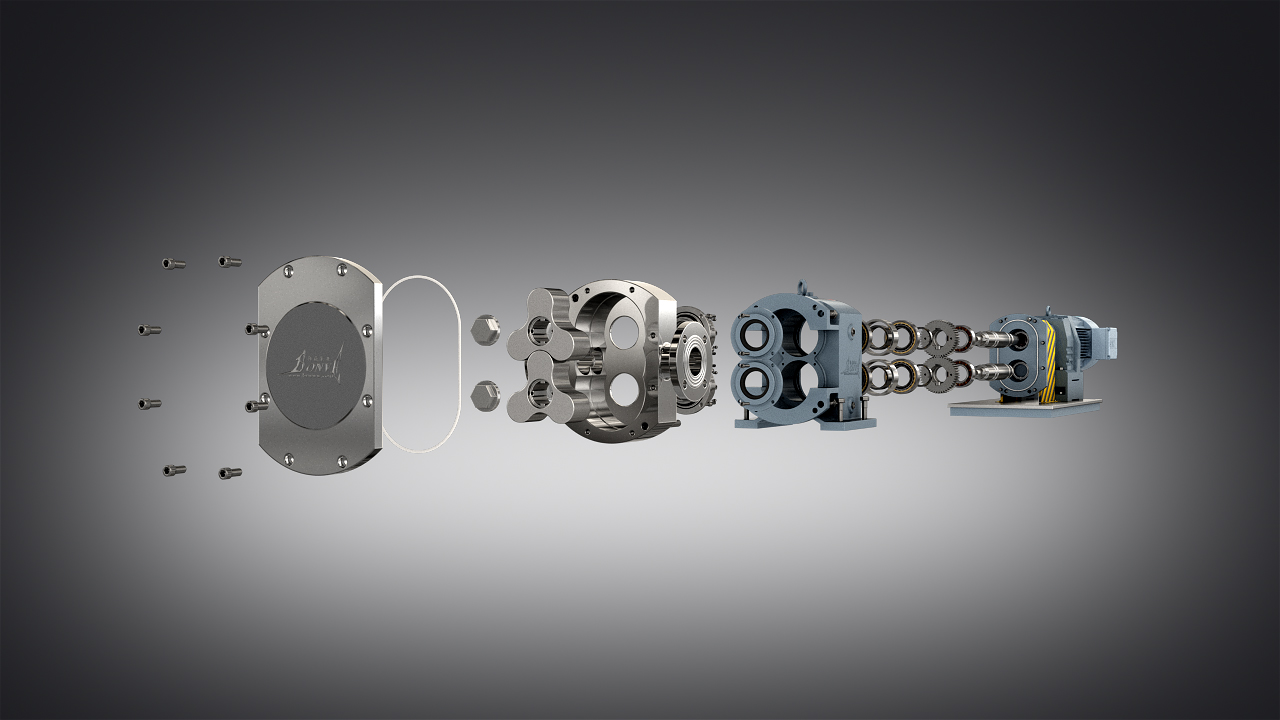

Pump structure diagram

The bare shaft pump is mainly composed of rotor, chamber, mechanical seal, gear box, gear and driving shaft. All these core components are processed by CNC. Our manufacturing technology has reached the international advanced level!

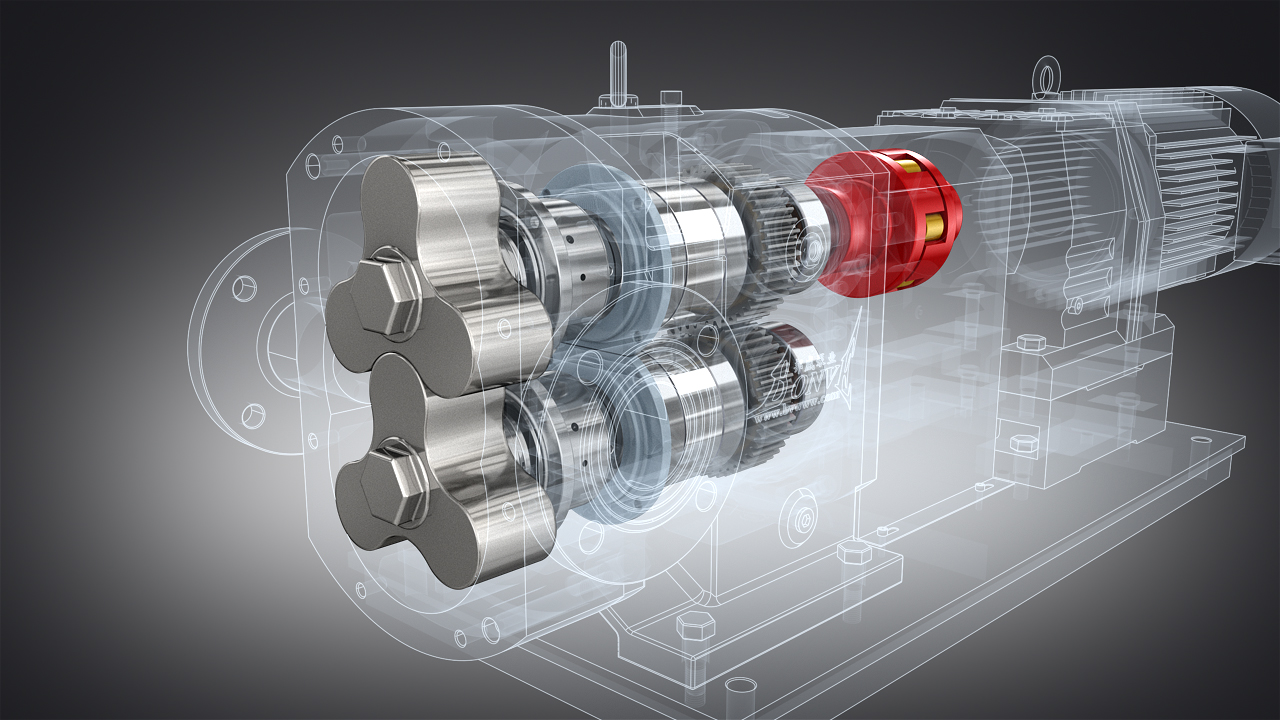

Special design

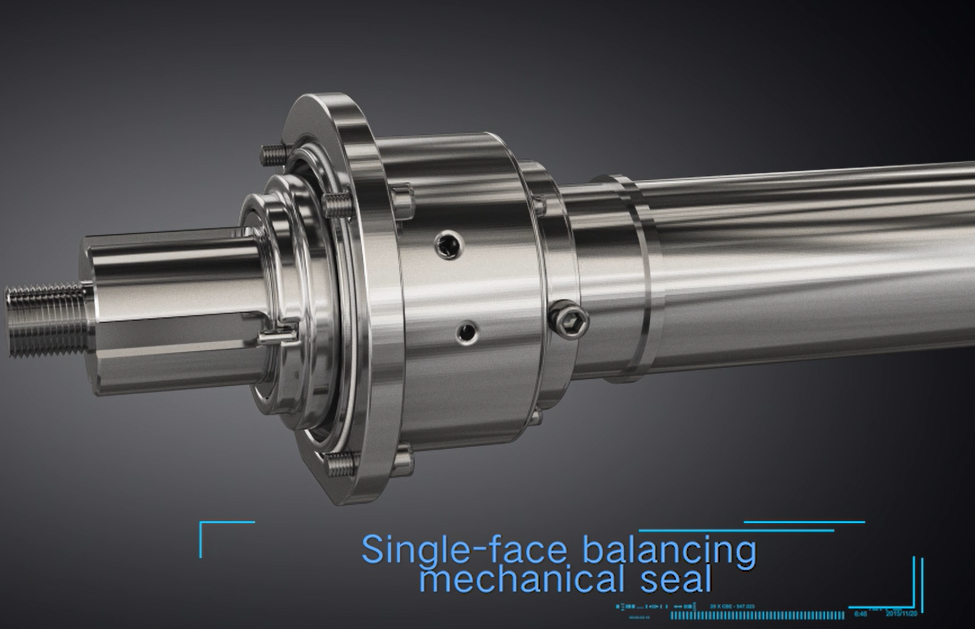

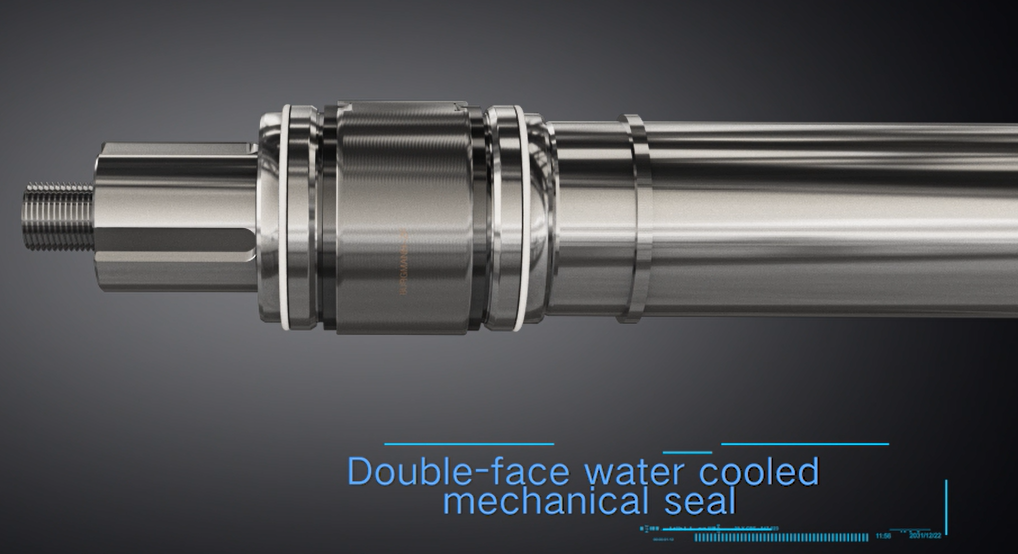

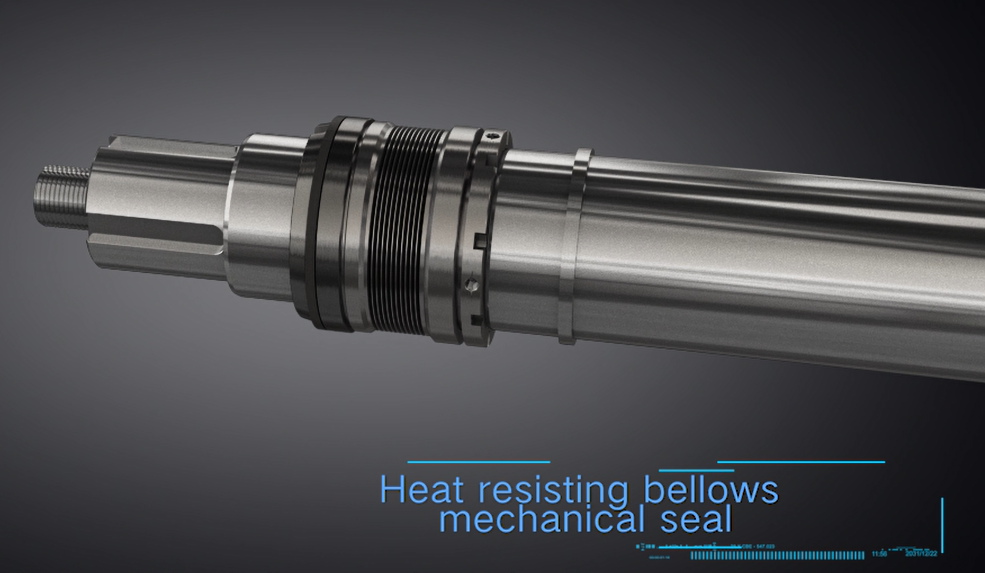

Seal Type: According to the different characteristics of the medium, you can have the Single-face balancing mechanical seal, Double-face water cooled mechanical seal, Heat resisting bellows mechanical seal, etc. Targeted seal used ensures zero leakage. All these types can be universally interchanged.

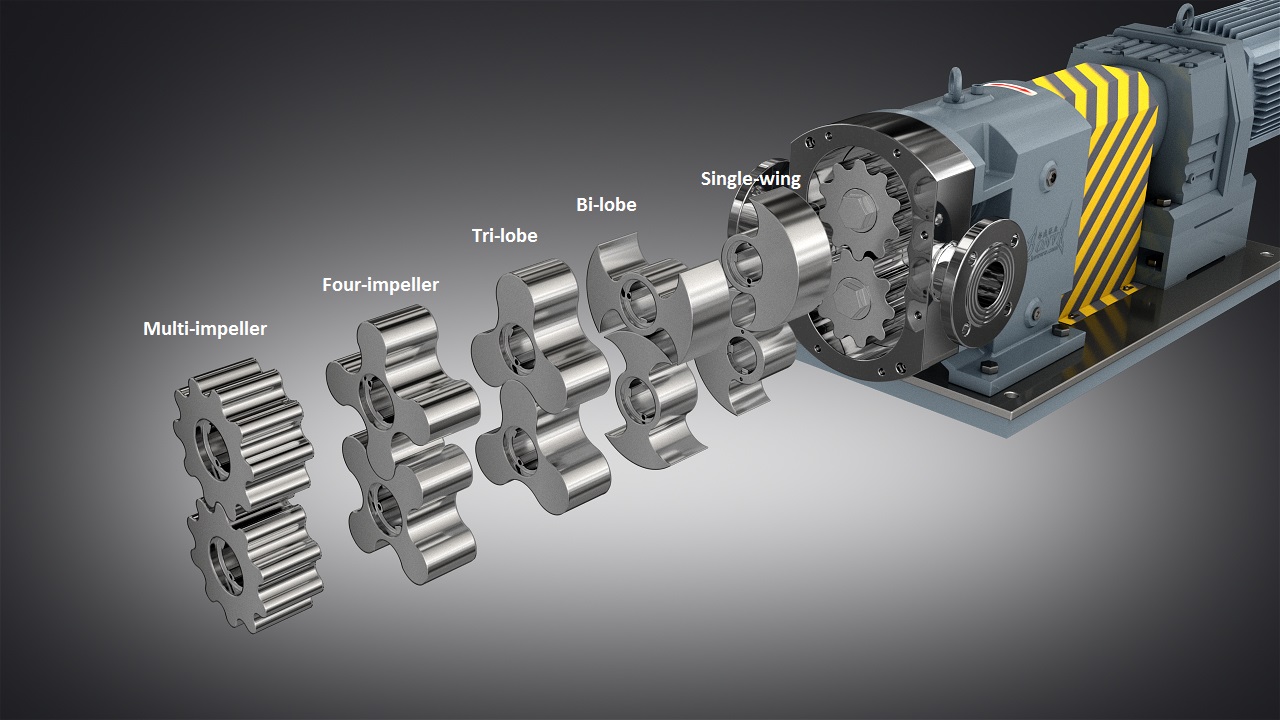

Rotor type: According to the different medium, the rotor designed has Single-wing, Double-wing, Tri-lobe, Four-impeller and Multi-impeller type, and all of these rotors can be universally interchanged.

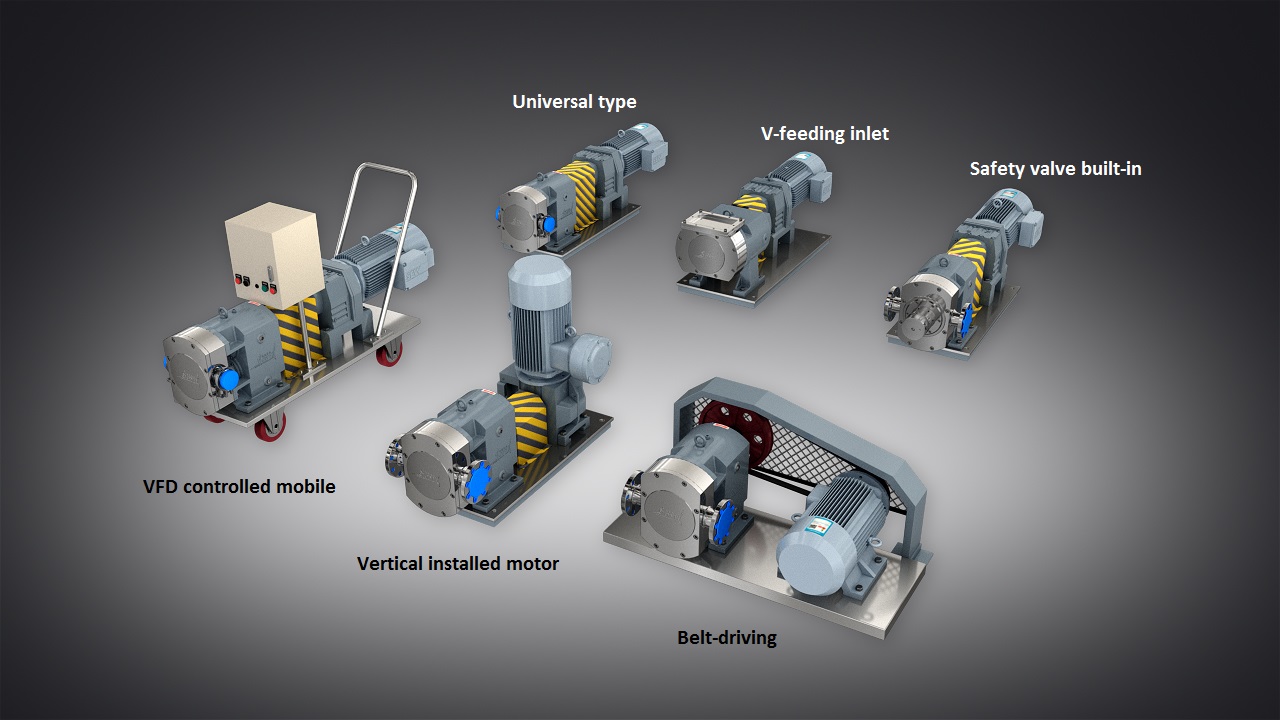

Pump Structure: Bonve designs a variety of pump structure which has a universal type, V-feeding inlet, safety valve built-in, VFD controlled mobile, vertical installed, pulley driving and etc. Meet the different requirements of site installation.

Bonve already served hundreds of pumps to Paper mills for Cooked starch every year and successfully to solve the pumping problem. For low maintenance, cost saving and long-life, Bonve lobe pump is a good choice to take replace of Screw pump.

Any interest to need a RFQ, contact cathy@bonvepumps.com

Below is a Selection guideline for your reference.

|

Liquid information

|

|

Your industry: __________ Liquid name:___________

|

|

Features: Sanitary [ ] Corrosive [ ] Poisonous [ ]

|

|

Viscosity:_______cp Density:_______ Temperature:_____℃ PH value:________

|

|

Solid content:_______ Max. size of particle:_______

|

|

Using condition

|

|

Capacity: Max. required__________ L/H Working required__________ L/H

|

|

Discharge pressure: Max. required__________Mpa Working required__________ Mpa

|

|

Suction pressure: Max. required__________Mpa Working required____________ Mpa

|

|

Delivery head required:____________ Vacuum:________ Mpa

|

|

Heating jacket required: Yes [ ] No. [ ] Heating temp.:_____℃

|

|

Liquid inlet/outlet direction: Horizontal [ ] vertical [ ]

|

|

Pipe size: Inlet___________ Outlet____________

|

|

Connection type required: Flange [ ] Thread [ ] Clamp [ ]

|

|

Installation type: Fixed [ ] Movable [ ]

|

|

Operating status: Continuous [ ] Interruption [ ]

|

|

Liquid contact material: SS304 [ ] 316[ ] 316L [ ] Others________

|

|

Special request_____________________________________

|

|

Order qty.

|