Bonve Rotary

Lobe Pumps for glycerin

Glycerol is also

called glycerine or glycerin. It is a colorless, odorless, viscous liquid

that is sweet-tasting and non-toxic. The glycerol backbone is found in

many lipids which

are known as glycerides. It is widely used in the food industry as a

sweetener and humectant in pharmaceutical. Glycerol has

three hudroxyl groups that are responsible for

its solubility in water and its hygroscopic nature.

How to choose pump?

Glycerol transfer pumps for food, cosmetics, and pharmaceutical,

must meet the hygiene requirements. Bonve offers its Sanitary Rotary Lobe Pumps for this

application. They are popular used because they offer superb sanitary

qualities, high efficiency, reliability, corrosion resistance and good

clean-in-place and steam-in-place (CIP/SIP) characteristics. They also offer

continuous and intermittent reversible flows and can operate dry for brief

periods of time. Flow is relatively independent of changes in process pressure,

too, so output is relatively constant and continuous.

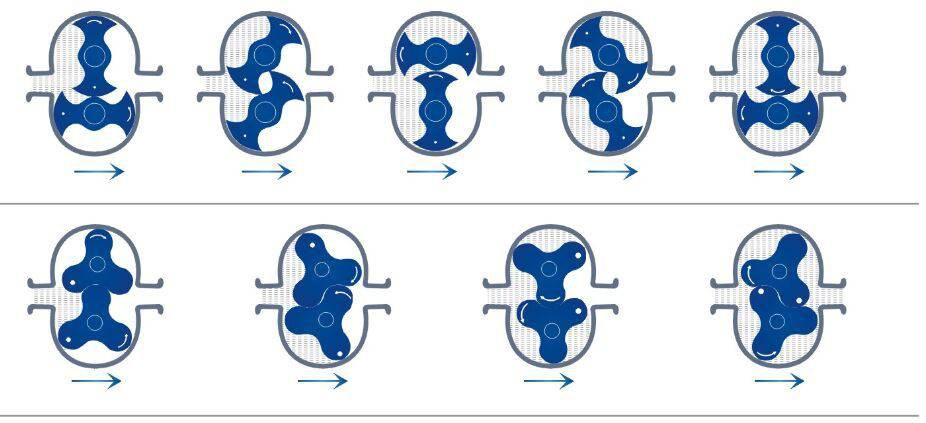

How Bonve pump works?

The even rotation of the rotor pair creates a vacuum on the

priming side of the pump, which can be defined by the direction of rotation of

the drive. This vacuum draws the liquid into the pump chamber. With further

rotation, the pumped medium is conveyed past the pump wall into the pressure

area. Up to six chamber charges are displaced with each drive rotation– depending on the rotor type. When the rotor is at a

standstill, the pump seals off almost

completely.

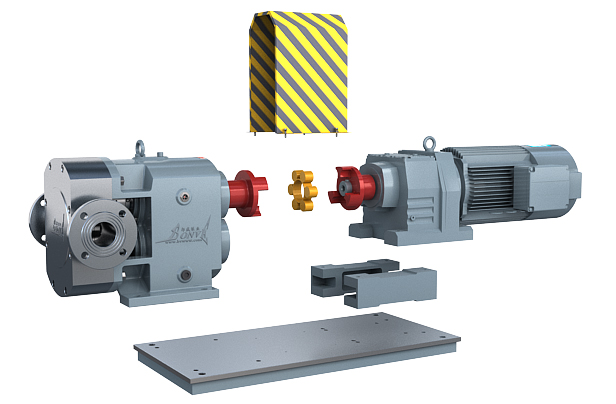

Pump main structure

Bonve Rotary lobe pumps are mainly composed of bare shaft pump, coupling, coupling guard, geared reducer with motor and base. The core parts are rotors, chamber, shaft, mechanical seal, gears, bearings and gear box, which are processed by CNC machine, which guarantees high precision and concentricity, results in a low maintenance and long life pump.

Pump structure advantage

Pump main technical parameters

|

Model

|

Displacement

(L/r)

|

Rotation

speed

(r/min)

|

Flow rate

(M³/h)

|

Pressure

range

(Mpa)

|

Electrical

power

(Kw)

|

Dia. of inlet and outlet (mm)

|

|

25BV6 /12-2

|

0.15

|

20-600

|

2

|

0.1-1.2

|

1.1-2.2

|

25

|

|

40BV6 /12-5

|

0.32

|

20-550

|

5

|

0.1-1.2

|

1.5-4

|

40

|

|

50BV6 /12-10

|

0.65

|

20-550

|

10

|

0.1-1.2

|

2.2-7.5

|

50

|

|

65BV6 /12-20

|

1.74

|

20-550

|

20

|

0.1-1.2

|

4-15

|

65

|

|

80BV6 /12-30

|

2.48

|

20-550

|

30

|

0.1-1.2

|

5.5-22

|

80

|

|

80BV6 /12-40

|

3.65

|

20-550

|

40

|

0.1-1.2

|

7.5-30

|

100

|

|

125BV6 /12-50

|

4.60

|

20-550

|

50

|

0.1-1.2

|

11-45

|

125

|

|

125BV6 /12-70

|

6.10

|

20-550

|

70

|

0.1-1.2

|

15-55

|

125

|

|

125BV6 /12-80

|

7.63

|

20-550

|

80

|

0.1-1.2

|

18.5-75

|

125

|

|

150BV6 /12-120

|

11.56

|

20-420

|

120

|

0.1-1.2

|

22-90

|

150

|

|

150BV6 /12-150

|

14.22

|

20-420

|

150

|

0.1-1.2

|

37-110

|

150

|

|

200BV6 /12-200

|

18.10

|

20-420

|

200

|

0.1-1.2

|

45-132

|

200

|

|

250BV6 /12-250

|

22.92

|

20-420

|

250

|

0.1-1.2

|

55-160

|

250

|

|

300BV6 /12-300

|

32.00

|

20-420

|

300

|

0.1-1.2

|

75-200

|

300

|

*This parameter list is tested with water as the medium. The parameters will vary from medium to medium. When you are selecting a model, please provide information about the medium.

Selection guideline

For a right pump selection, below information are necessary to consider. Email to trade@bonvepumps.com to ask for editable form to fill in.

|

Liquid information

|

|

Your industry: __________ Liquid name:___________

|

|

Viscosity:_______cp Density:_______g/cm³ Temperature:_____℃ PH value:________

|

|

Solid content:_______ Max. size of particle:_______

|

|

Using condition

|

|

Capacity: Max. required__________ L/H Working required__________ L/H

|

|

Discharge pressure: Max. required__________Mpa Working required__________ Mpa

|

|

Suction pressure: Max. required__________Mpa Working required____________ Mpa

|

|

Delivery head required:____________ Vacuum:________ Mpa

|

|

Heating jacket required: Yes[ ] No.[ ] Heating temp.:_____℃

|

|

Liquid inlet/outlet direction: Horizontal[ ] vertical[ ]

|

|

Pipe size: Inlet___________ Outlet____________

|

|

Connection type required: Flange[ ] Thread[ ] Clamp[ ]

|

|

Installation type: Fixed [ ] Movable[ ]

|

|

Operating status: Continuous[ ] Interruption[ ]

|

|

Liquid contact material: SS304[ ] 316[ ] 316L[ ] Others________

|

|

Special request_____________________________________

|

Bonve is an expert of Rotary lobe pump manufacturer in China. It

introduces advanced production equipment and produces high precision pump

to meet customers' targeted application. With your specific duty, pls email to trade@bonvepumps.com and ask for a pump sulution.