All purlins, channels, steel frames used in door and steel structure roll forming machines are customized for users in the world.

Product Name: Steel Frame Structure Roll Forming Machine M Purlin Shape

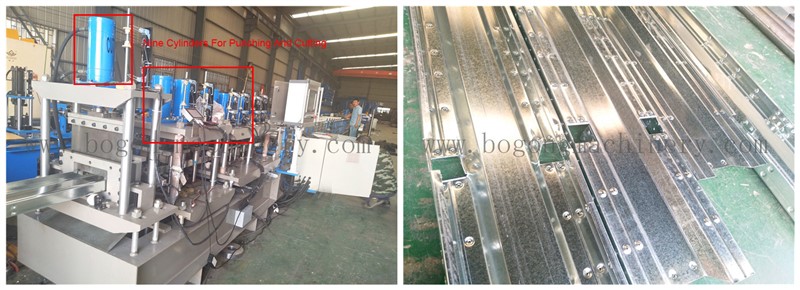

This M280 Steel Frame Structure Roll Forming Machine has been designed with nine cylinders for all holes need by steel frame system. The punching die list is as below.

|

Description

|

Quantity

|

|

45*12mm punching die(for cutting side rolling material)

|

2sets

|

|

Ф3.3mm beehive hole die

|

2 sets

|

|

60*30mm punching die (for cable used hole)

|

1 set

|

|

89*50 sqaure hole die ( for cutting plate web)

|

1 set

|

|

45°angle cutting die

|

1 set

|

|

plate web shrink die

|

1 set

|

|

Cutting blades

|

1 set

|

There are one pre-cutter for material head and another post cutter for purlin shapes.

Whole Steel Frame Structure Roll Forming Machine M Purlin Shape chooses two pieces of cutting blades cutting, no waste, because of too many holes to punching, the producing line roll forming speed is lower than common purlin machines. PLC system to combine all actions worked one by one step, no mistake and more precision accuracy.

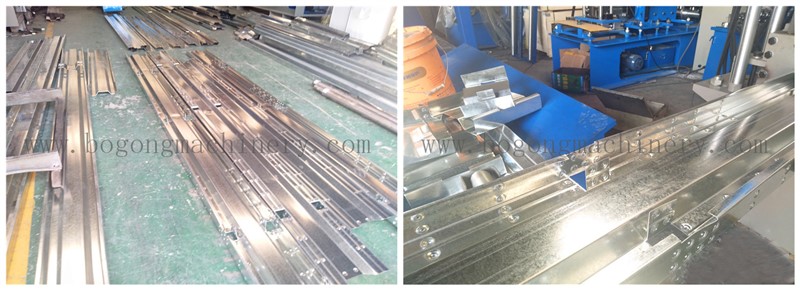

Steel frame structure samples produced by this Steel Frame Structure Roll Forming Machine. What we should take care is ensure all the samples straighten enough, the holes are in their correction position and the cutting position are smoothly.

Technical Parameters

|

Description

|

Reference Picture

|

|

Size

|

12500*1200*1550mm

|

|

Weight

|

12000KGS

|

|

Main Servo Motor Power

|

22KW

|

|

Hydraulic Motor Power

|

5.5KW

|

|

Forming Steps

|

20 steps roll forming

|

|

Processing Speed

|

About 5-8m/min

|

|

Voltage

|

380V/50HZ/3PH

|

|

Tolerance Of Forming

|

0.75mm

|

|

Forming Thickness

|

1.0mm -3.0mm

|

|

Height

|

100mm

|

|

Width

|

280mm

|