Steel rolling doors forming machine, garage door roll forming machines, door guiderforming machines are acceptance for customizing.

Product name: T Profile Roller Shutter Door Roll Forming Machine Garage Door Used

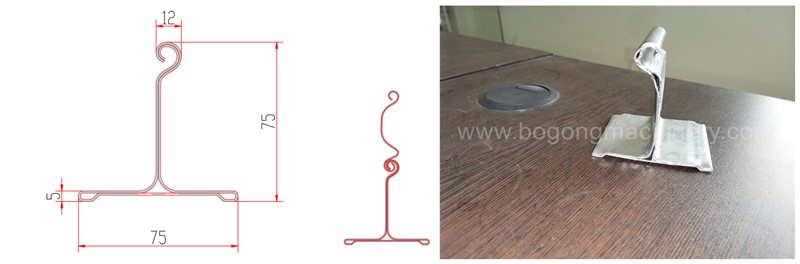

Sheet Sample

This T Profile Roller Shutter Door Roll Forming Machine is used roll forming the bottom piece of roller shutter doors. The raw material width is 324mm, suit for 1.0-1.5mm thickness galvanized sheet. See below sample for reference.

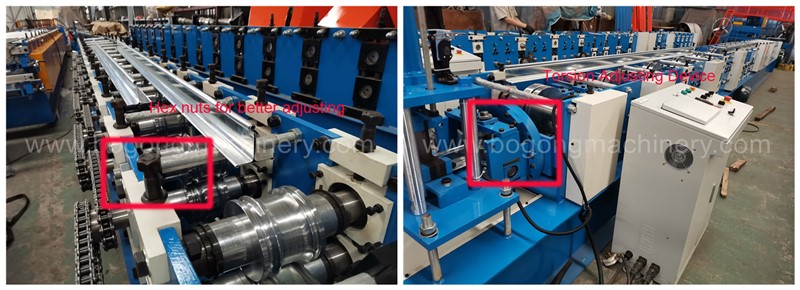

Main Machine Details

Our T Profile Roller Shutter Door Roll Forming Machine all stations vertical locked screw are with hex nuts, with these hex nuts, if necessary need to adjust the up and down rollers span for different steel sheet thickness, it is good for operator to adjust the with these type of hex nut by spanner.

Due to this T profile roller shutter door sample is high and easy to be torsion, our designer has designed this torsion adjusting device, once T profile is not straight enough, operator can adjust this device to right side or left side to get correct beautiful T profile sample.

This set of T Profile Roller Shutter Door Roll Forming Machine has chose three pieces of cutting blades for cutting off. This type of cutting blades is good for ensure the cutting position won't be deformed very serious, but it will waste some of raw material. See the final T profile sample produced by this T Profile Roller Shutter Door Roll Forming Machine, it is straight and vertical enough.

Technical Parameters

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH or customized

|

|

Driving Motor

|

7.5KW

|

|

Forming Steps

|

20steps

|

|

Working Speed

|

10-15m/min

|

|

Thickness for Steel

|

1.0-1.5mm

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post cutting, no waste cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel

|

|

Raw Material

|

Galvanized steel

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

11000*950*1050mm

|

|

Weight

|

7000KGS

|

Need More information? Contact with us soon.