Main Parameter

1、Overall size:32.7m×6.5m x 4m(for reference only)

2、Machine size:28.8m ×4.5m ×3.5m(based on the product provided by client)

3、Design speed:700 pcs per min

4、Work speed:450-550pcs per minute

5、Rejection rate:≤2%(excluding scrap caused by hot melt,materials splicing or joint)

6、Power source:380V,50/60HZ(3phase.4lines+ground wire)

7、Machine capacity:290kW approximately

8、Air pressure:0.6-0.8Mpa

9、Machine weight:76Tons approximately

Configuration

1、Product structure:Upper&lower tissue,Cotton core(mix with SAP),ADL,Backsheet,Frontal tape,Topsheet hydrophilic nonwoven,Leak cuff hydrophobic nonwoven,Spunbond small ear,Elastic big ear.

2、Product size:NB/S/M/L/XL.

3、Product specification :Length:380mm~560mm.

4、Program system:Servo driven,intelligent HMI touch screen man-machine interface.

5、Tension system:Tension control with buffer system,automatic web guiding system,to ensure materials stable working at ZERO speed splice.

6、Driven system:Servo drive,digital size change,ensure run synchronously at full process.

7、Safety system:Safety guard for operating side,emergency stop switch,security identifier,safety pull wire at driven side.

8、Packaging system:Auto stacker(dual push dual exit)and auto bagger to be defined by customer need

9、Web guiding system:Germany BST/USA FIFE.Customized function available

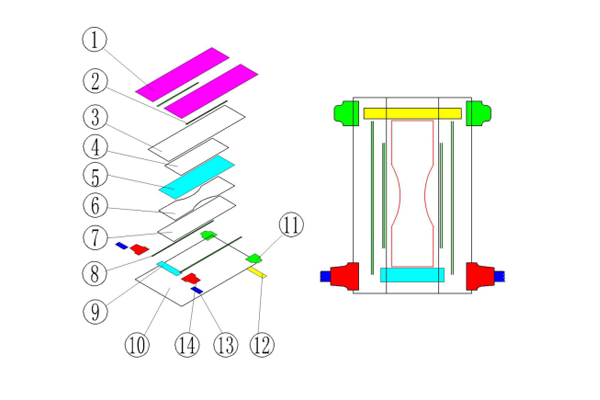

Product structure

|

1.Hydrophobic non woven

|

8.Leg elastic

|

|

2.Leak elastic

|

9. Waistband elastic

|

|

3.Top sheet non woven

|

10.PE film back sheet

|

|

4.ADL

|

11.Small ear

|

|

5.Upper tissue

|

12.Frontal tape(absorbent paper)

|

|

6.Cotton core

|

13.Big ear

|

|

7.Lower tissue

|

14.Side tape

|