Thermocouple Manaul Feeding Hot Bar Soldering Machine

Hot Bar Soldering Machine Principle:

A 2000W transformer is used to generate a large current with low voltage, which is heated rapidly through the welding joint. Pulse current refers to the on and off frequency ratio of current. The larger the pulse ratio is, the larger the current output is, and the faster the welding joint temperature rises, it is how a hot bar soldering machine works.

;

Hot Bar Soldering Machine Features:

• The heating rate is customized to meet different products.

• Molybdenum alloy head to ensure temperature stability, fast heating speed and long service life.

• The level of soldering head is adjustable, to ;ensure uniformpart assembly processing.

• Digital display to control temperature, easy and clear.

• With digital pressure meter, can be preset pressure range.

• Special welding materials.

• It is equipped with precise PID control, phase Angle instead of pulse drive.

• Little vibration, low noise, no voltage fluctuation.

• Molybdenum alloy soldering head instead of traditional titanium alloy, warmmingfaster, good coefficient of heat transfer, wear-resisting.

;

Hot Bar Soldering Machine Configuration:

Under pressure cylinder : SMC

Pressure display table : Analog

Magnetic cylinder sensor switch : SMC

Solenoid valve : made in Taiwan

Connectors and trachea : made in Taiwan

Filter regulator : made in Taiwan

Precision cylinder under pressure regulator : SMC

Control system: independent research and development ( Chinese )

Power transformer : 220V, 2000W

Driver module : 45A

Vacuum Generators : SMC

Button switch: Schneider

Relay: Omron

Chassis components: aluminum plus bending parts

Hot Bar Soldering Machine Specification:

|

Machine size

|

610×410×450mm

|

|

Working area

|

Max 150*150mm

|

|

Machine weight

|

62Kg

|

|

Working air pressure

|

0.6-0.8Mpa

|

|

Fixture quantity

|

2

|

|

Thermode head size

|

Max 40*3mm

|

|

Welding precision

|

pitch 0.2mm

|

|

Pressing time

|

1~99.9s

|

|

Temperature settings

|

RT~500℃ tolerance ±5℃

|

|

Welding pressure

|

1~20Kg

|

|

Temperature settings

|

Two

|

|

Working environment

|

10-60℃,40%-95%

|

|

Power supply

|

AC220V±10% 50HZ,2200W

|

|

Alignment mode

|

CCD + LCD Monitor

|

|

Feeding mode

|

Manual

|

|

Starting mode

|

Press start buttom

|

|

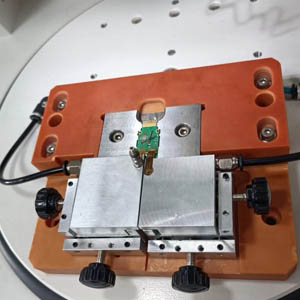

Rotation Platform

|

Cylinder control,tolerance<0.02mm

|

;

Hot Bar Soldering Machine Parameters:

|

Temperature range

|

50℃ to 500℃

|

|

Temperature accuracy

|

±1°C

|

|

Bond timer

|

0-12 seconds

|

|

Bond air pressure

|

0.4-0.6MPa

|

|

Pressure accuracy

|

±0.05MPa

|

|

Max bond ;force

|

1100N

|

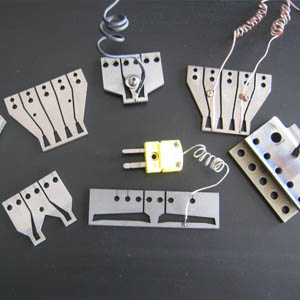

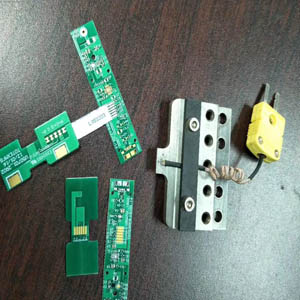

Customized Thermode and Fixtures:

; ;

; ; ; ;

; ;

Thermode Head Introduction:

Molybdenum alloy head to ensure temperature stability, fast heating speed and long service life.

The level of soldering head is adjustable , to ensure uniformpart assembly processing

Digital display to control temperature,easyand clear

With digital pressure meter, can be preset pressure range

Special welding materials

It is equipped with precise PID control, phase Angle instead of pulse drive.

Little vibration, low noise, no voltage fluctuation

Molybdenum alloy soldering head instead of traditional titanium alloy, warmmingfaster, good coefficient of heat transfer, wear-resisting

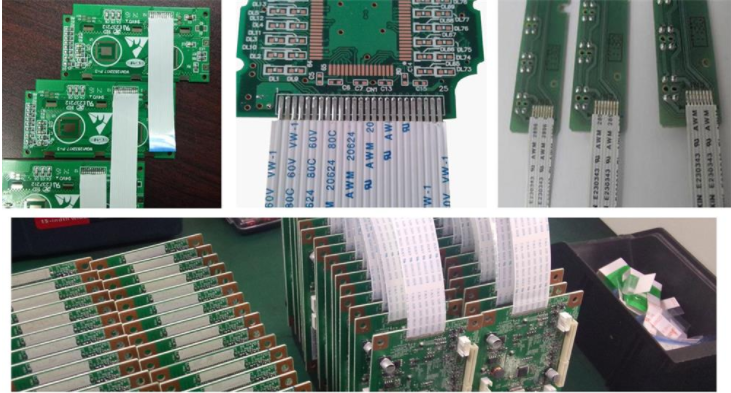

Hot Bar Soldering Machine ;Application:

During hot bar soldering, a thermode is heated to a specific temperature by a pulse heat power supply. The thermode applies sufficient heat to cause the solder to melt and flow, after which the components are cooled under pressure, thereby creating an electro-mechanical bond between the two components. It is available for FFC to PCB soldering, FPC to PCB soldering, wires to PCB soldering, copper to copper soldering, ect.

Our Certificate:

Company Profile:

2008, Dongguan factory established, and start producing standard v-cut PCB separators and hot bar soldering machines.

2010, Our products are widely sold in local market.

2012, Start producing customized v-cut depaneling and PCB router.

2014, ;Expand our sales team for providing better service to more customers.

2015, Start manufacturing laser depaneling machines.

2017, Start manufacturing ;soldering robot and screwdriver machines.

2018, HK company established.

2019, Huizhou factory established, due to expansion.

2020, Business expansion again, products covering PCB depaneling, PCB soldering, screwdriver system, etc. ;

2021, Our machines cover all Chinese market and also popular in America, Europe, South Asia, East Asia, etc.