Product Information

UTS-TF04 Tracking index test equipment is to determine the proof and comparative tracking

indices of solid insulating materials on pieces taken from parts of equipment and on plaques

of material using alternating voltages.

Application

Lighting equipment, low-voltage electrical appliances, household appliances, machine tool

electrical appliances, motor, electric tools, electronic equipment, electrical instruments,

information technology equipment, insulation materials, engineering plastics industry,

electrical fittings, auxiliary parts.

Working Principle

The working principle of Tracking index tester is to that the conducting liquid (0.1%NH 4 CL)

of required volume in the required height (35mm ) and required time (30s) drops with the

voltage between the platinum electrodes (2mm× 5mm )on the surface of solid insulating

material. Thus the users evaluate the tracking resistance performance of solid insulating

material surface under the combined influence of electric field and humid or contaminate

medium. In a word, this device is used to measure the compare tracking index (CT1) and

electrical resistance index (PT1).

Standards

GB4207, IEC60112

Features

1. Adopt 2mm thick galvanized cold plate which shaped by Germany trumpf CNC machining

center, with beautiful and high grade appearance.

2. Outdoor grade powder baking technology, which enhance anti-smog corrosion resistance

ability. High quality and without color changing.

3. Equipped with German imported temperature sensor used in airplane and resistance to

high temperature with longer service life.

4. Silent design toughened glass sliding observing window.

5. Step motor control stroke, accurate location and without buffer.

6. With the function of program parameter setting, the test parameters can be programmed

to be stored in the controller.

7. With the judging function to assess that test is qualified or not.

8. Import control components adopted.

9. Droplet time and volume control is high precision.

10. Adopt advanced voltage control and protective system.

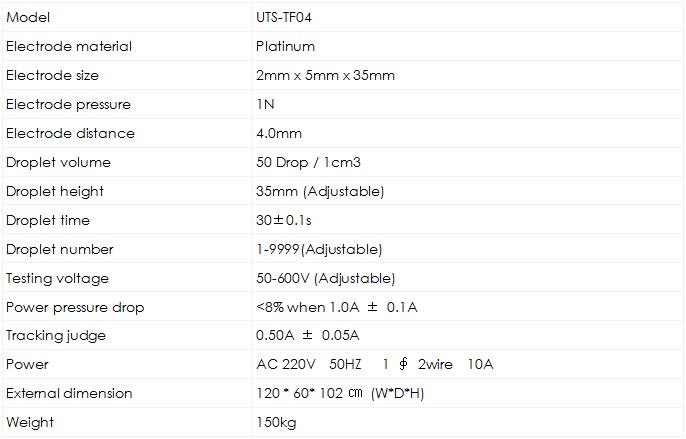

Key Specifications

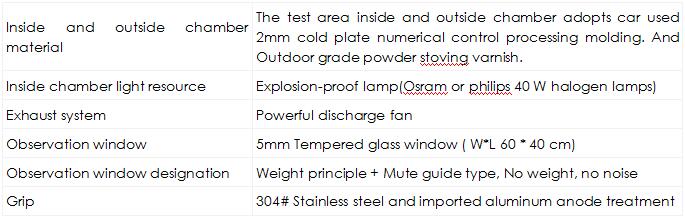

The structure designation

Control System

Configuration

Application