TU-883

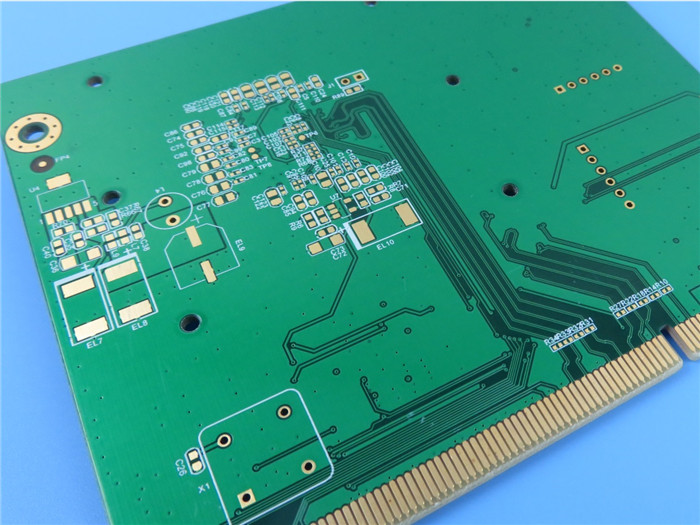

Multi-layer Printed Circuit Board (PCB) HDI Low Loss High Temperature PCB With 90

Ohm Impedance Controlled

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

Brief

Introduction

It’s also a type of HDI circuit

boards (N+1+N) with 0.1mm laser drill. This is also a type of impedance

controlled PCB, 90 Ohms and 50 Ohms are controlled on each signal layers with

10% tolerance. The copper foils are 1 oz and half oz used alternately between

layers. The whole PCB is 3.0mm thick, with immersion gold on pads, green solder

mask and white silkscreen.

Applications

Radio

frequency

Backplane,

High performance computing

Line

cards, Storage

Servers,

Telecom, Base station, Office Routers

Detailed

Specifications

|

Item

|

Description

|

Actual

|

Result

|

|

1. Laminate

|

Material Type

|

TU-883

|

ACC

|

|

Tg

|

170℃

|

ACC

|

|

Supplier

|

TUC

|

ACC

|

|

Thickness

|

2.8-3.1mm

|

ACC

|

|

2.Plating thickness

|

Hole Wall

|

26.51µm

|

ACC

|

|

Outer copper

|

41.09µm

|

ACC

|

|

Inner Copper

|

15µm / 31µm

|

ACC

|

|

3.Solder mask

|

Material Type

|

TAIYO/ PSR-2000GT600D

|

ACC

|

|

Color

|

Green

|

ACC

|

|

Rigidity (Pencil Test)

|

5H

|

ACC

|

|

S/M Thickness

|

20.11µm

|

ACC

|

|

Location

|

Both Sides

|

ACC

|

|

4. Component

Mark

|

Material Type

|

IJR-4000 MW300

|

ACC

|

|

Color

|

White

|

ACC

|

|

Location

|

C/S, S/S

|

ACC

|

|

5. Peelable Solder Mask

|

Material Type

|

/

|

|

|

Thickness

|

/

|

|

|

Location

|

/

|

|

|

6. Identification

|

UL Mark

|

YES

|

ACC

|

|

Date Code

|

2921

|

ACC

|

|

Mark Location

|

Solder Side

|

ACC

|

|

7. Surface Finish

|

Method

|

Immersion Gold

|

ACC

|

|

Nickel Thickness

|

4.06µm

|

ACC

|

|

Gold Thickness

|

0.056µm

|

ACC

|

|

8. Normativeness

|

RoHS

|

Directive 2015/863/EU

|

ACC

|

|

REACH

|

Directive 1907 /2006

|

ACC

|

|

9.Annular Ring

|

Min. Line Width (mil)

|

4.8mil

|

ACC

|

|

Min. Spacing (mil)

|

5.2mil

|

ACC

|

|

10.V-groove

|

Angle

|

/

|

|

|

Residual thickness

|

/

|

|

|

11. Beveling

|

Angle

|

/

|

|

|

Height

|

/

|

|

|

12. Function

|

Electrical Test

|

100% PASS

|

ACC

|

|

13. Appearance

|

IPC Class Level

|

IPC-A-600J &6012D

Class 2

|

ACC

|

|

Visual Inspection

|

IPC-A-600J &6012D Class 2

|

ACC

|

|

Warp and Twist

|

0.21%

|

ACC

|

|

14. Reliability Test

|

Tape Test

|

No Peeling

|

ACC

|

|

Solvent Test

|

No Peeling

|

ACC

|

|

Solderability Test

|

265 ±5℃

|

ACC

|

|

Thermal Stress Test

|

288 ±5℃

|

ACC

|

|

Ionic Contamination Test

|

0.56µg/c㎡

|

ACC

|

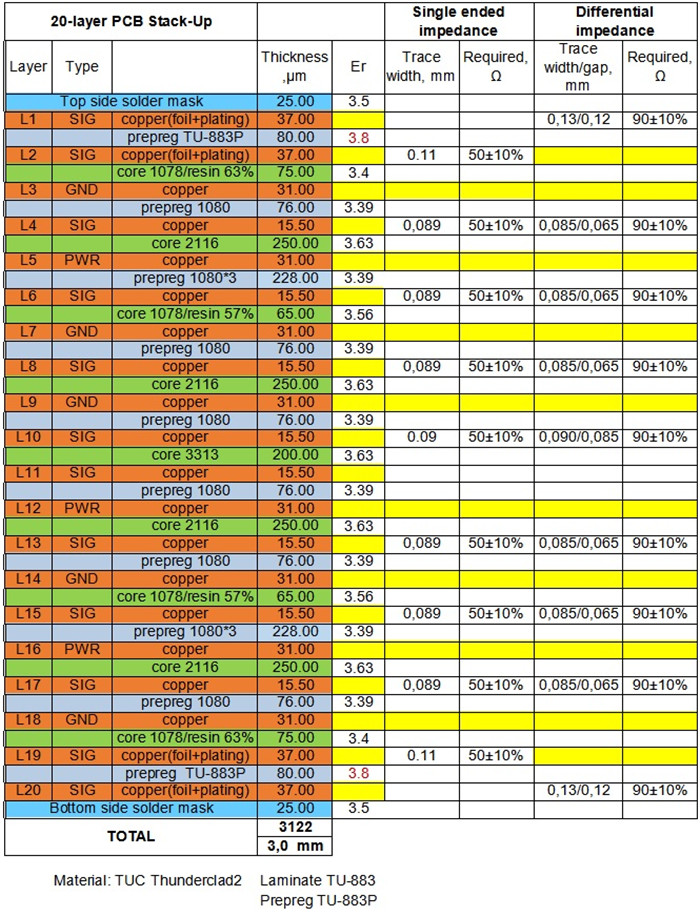

Stackup

& Impedance Controlled

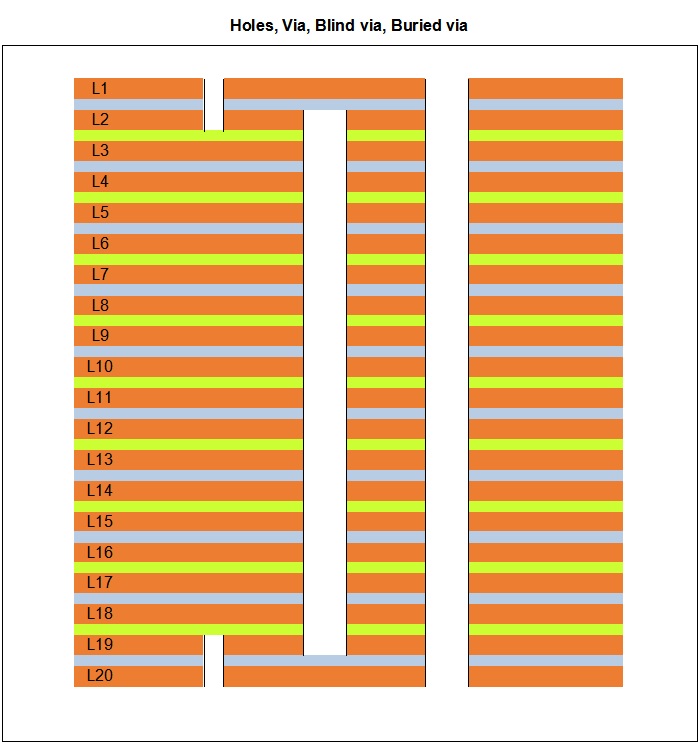

HDI

vias

MANUFACTURING PROCESS:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS: