Higao Tech offer high quality

ultrasonic vibrating screen machine for separating powder and pellets with best price in china. Ultrasonic vibrating screen machine is used mostly for very fine powder that can not be separated by normal screening machines..

1. Introduction:

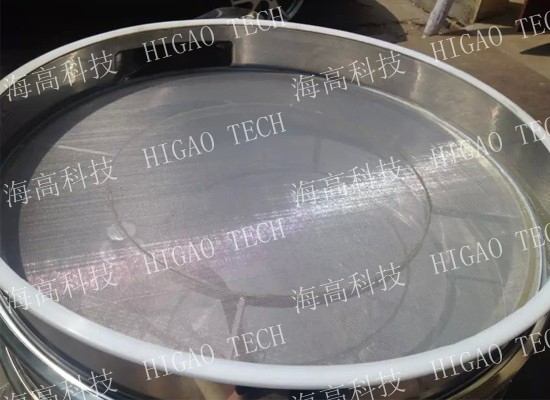

Ultrasonic vibrating screen machine is a size separating equipment which adopts advanced intelligent ultrasonic controller and has solved many problems caused by single frequency.

It is the reasonable combination of ultrasonic function and vibrating screener.

The working principle of ultrasonic vibrating screen is adding an ultrasonic energy transform device on the screen surface of 3D vibrator separator and filter. This device can make the screen surface superpose ultrahigh frequency vibrational energy, so that it can keep clear of the mesh and achieve the ideal screen situation.

2. Features:

2. Features:

1) Prominent advantages in solving materials containing high adsorption, easy reuniting, high electrostatic, high precision, high density, light specific gravity etc.

2) Realizing high precision. Can separate 25μm powder, can filter 10μm liquid materials.

3) With sieve self-cleaning function, no-blocking sieve, stable sieving efficiency.

4) Have the function of effectively controlling sieving granularity scale.

5) Ultrasonic vibrating sieving machine can be used with single layer/deck or multilayer/more decks.

6) A set of intelligent ultrasonic generator can use three controllers at the same time.

7) Can work 24hours nonstop and do not need to cool down the temperature of the power and energy exchanger.

8) Can keep the features of the processed materials.

9) Sieving precision can be enhanced by 1-100% and capacity can be enhanced by 1-10 times.

10) Engergy exchanger and sieve are connected by screws and clamps, easy to dismantle and install for cleaning.

11) Do not use rubber balls to clean the sieve. Avoid second contamination from the wearing of the rubber balls.

3. Applied materials:

3. Applied materials:

carborundum/silicon carbide, alloy powder, Molybdenum powder, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder dope, quartz powder, malt powder, virus powder, virazole powder, coffee powder, electromagnetism powder, cathode materials, laser powder.