Structure and working principle

JCUM multipurpose pulverizer is a universal type of replaceable mill with 4 kinds of rotor structure. According to the different requirements of the comminution, pin rod type, rotor type, grinding disc type and knocking rod rotors can be selected respectively. The pin is suitable for using superfine comminution and smashing of sticky material. The rotor is suitable for brittle material and fibrous material. The grinding and grinding disc type is suitable for crushing of plastics, and percussion stick type is suitable for pre-crushing and coarse crushing.

The machine consists of the parts of the machine shell, the door, the rotor, the stator, the spindle, the main shaft, the main shaft gas seal, the feeding device,etc. The sealing ring between the shell and the door is to prevent the leakage of dust. The material can be quantified into the crushing chamber through the adjustable vibration feeder to ensure the uniformity and continuity of the feeding process.

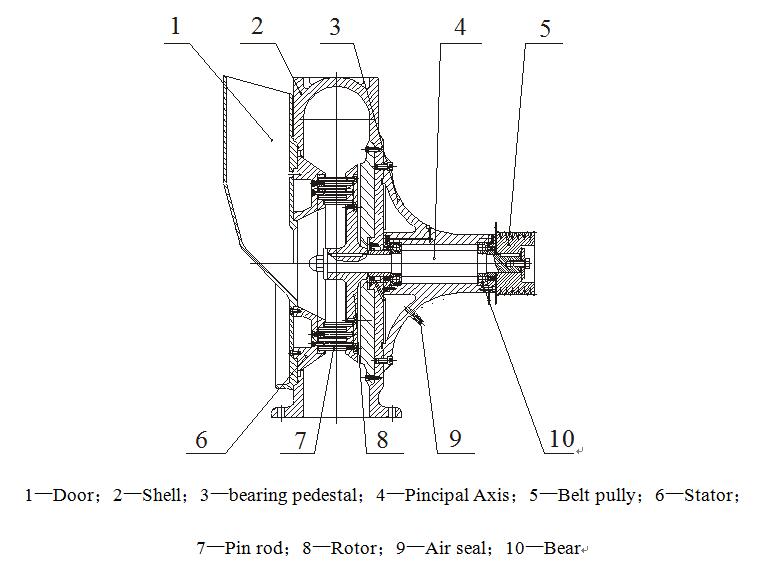

1.The internal structure of pin rod type

The rotor and stator consist of a closed comminuted

cavity. When the material is sent into the comminuted cavity through the

feeding device, the material also follows the speed of rotation and moves

outward in the direction of centrifugal force under the effect of high speed

rotation of the rotor. During this process, the material collided with the

rotor pin and the pin rods on the stator,then lead to be smashed. Because the

rotor and the stator have 3~4 layers of pin rods, the crushing effect of the

material is relatively sufficient, so that the material fineness and the

particle size is uniform. During the comminution process, the smashing area

inhaled a large amount of air, which played the role of cooling machines,

abrasives and conveying materials. The bearing part is designed with a

compressed air seal device, which effectively prevents dust from entering the

bearing and prolongs the service life of the bearing.

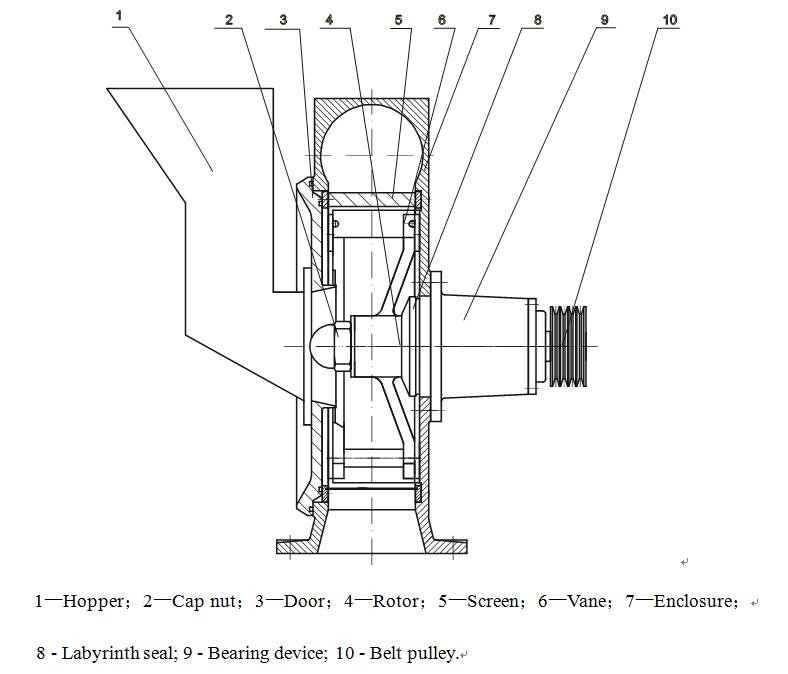

2. The internal structure of the rotor type

The motor drives the spindle and the turbine to rotate

at a high speed, through the high speed rotation of the turbine to absorb a

large amount of air, and the material and air flow with the high speed rotating

turbine. The grinding zone of the turbine and the grinding block on the screen

ring is compact, so that the material entering the machine is tightly rubbed in

the rotating air and strongly impacted on the inner edge of the turbine blade,

and again lapping in the gap between the blade and the grinding block. When the

material meets the requirement of product fineness, the material is filtered

out from the screen and discharged through the lower chamber of the chassis. In

this process, the large amount of air that the turbine sucked into has played

the role of cooling machine, abrasive and conveying fine powder. The fineness

of the material depends on the nature of the material and the size of the

screen, as well as the throughput of the material and air.

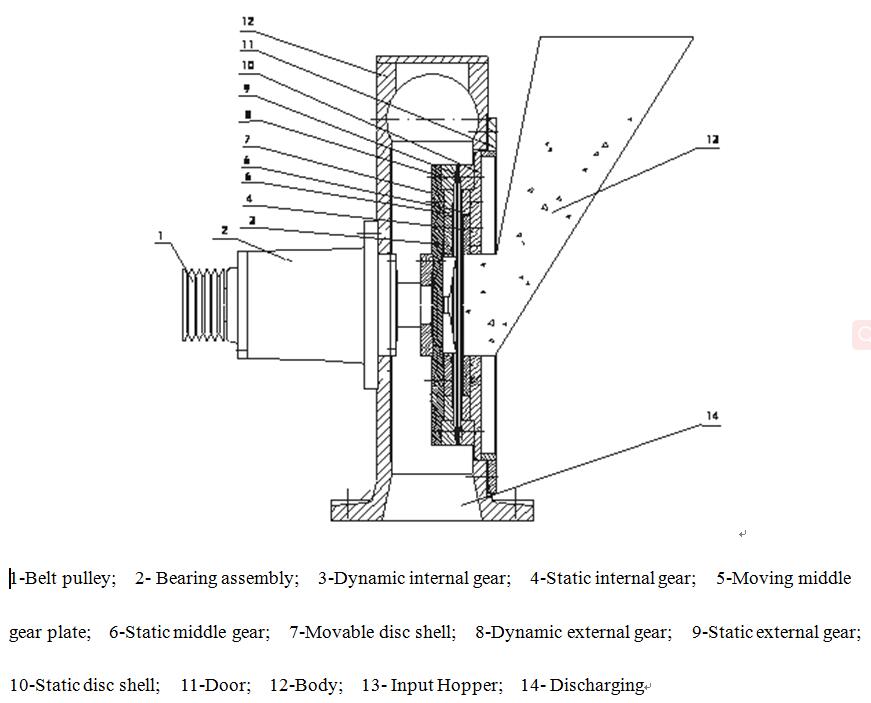

3. Grinding disc type

The

material enters into the crushing chamber composed of the static disk and the

moving disc from the feed pipe. The material is constantly cut, impacted and

rubbed because of the high speed rotation of the movable disk and the effect of

the fan. The particles are getting smaller and moving outward. Finally, the

discharge pipe is collected by the aggregate system.

Applications

Food: sugar, rice, corn, starch, oat, flour, soya bean, pea, lentil, spice, cocoa powder, potato powder, coffee, salt, milk powder, onion, vegetable, grape powder, etc.

Chemical raw materials: pigment, coloring matter, alumina, iron oxide, Zinc Oxide, copper powder, detergent, etc.

Plastics: polyethylene, PVC, polystyrene, rubber, epoxy resin, etc.

Packing and building materials: limestone, gypsum, fluorite, mica, barite, pottery, asbestos, straw, wheat straw, wood pulp, oatmeal shell, fruit shell, fabric, etc.