Application

H018 Whole Sole Flexing Machine, to measure the material's resistance to incision elongation

(cut growth) during repeated flexing, especially for outsoles of protective footwear, including

soles.

The machine has three vertical or horizontal stations available for customized and is easy

tooperate. Loading, unloading and measurements are also much easier to carry out with

the workstations provided.

The sample flexes at speed of 140 times per minute, and the exact number is recorded in a

counter that has been preset to the required number of flexing.

A fixture can be used to position the steel chisel, which can be used to support the sample

after the initial chipping. All mobile parts that need access are fully protected with a fully

interlocked security cover to ensure that the machine complies with the latest security

regulations. A manual device can be used to measure the hardness of the outer bottom

and check whether the outer bottom must be twisted in accordance with EN ISO 20344.

UTS also provide a version of this machine for testing at low temperatures allowing tests to

be conducted down to -20°C.

Test Principle

This machine is suitable for repeated bending test of sole.During the test, the sample sole

was fixed between two clamping tools. After repeated bending at certain angles and times,

the incision length of the sample sole was examined. With the point return function,

convenient to save time.

Features

Workstations Variety

Test position 1, 2, 3, 4, 5, 6 or more, customized.

Safety Cover

Safety cover equipped to ensure test security. Test and count stopped automatically once

cover opened . Restart running to continue the counting.

Necessary Accessory

Necessary accessory including spanner and Chisel cutter(2mm) provided to conduct tests

after receive our instrument.

Simple Operation

Sample installation, testing times preset, then you can start your test in ease.

Standards

ISO 17707, SATRA TM161, ISO20344 , ISO20347, AS/NZS 2210.2,GB/T 20991,

QB/T 2885, DIN 53543

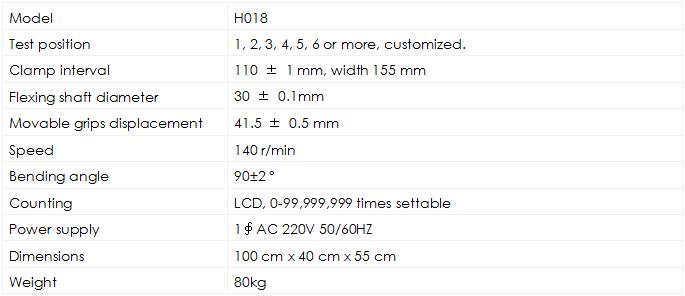

Key Parameters

Accessory

Application