BLOCK MAKING MACHINE

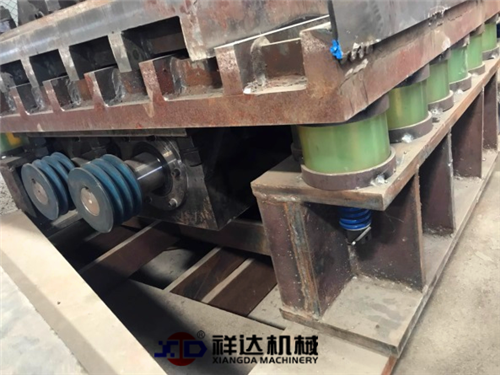

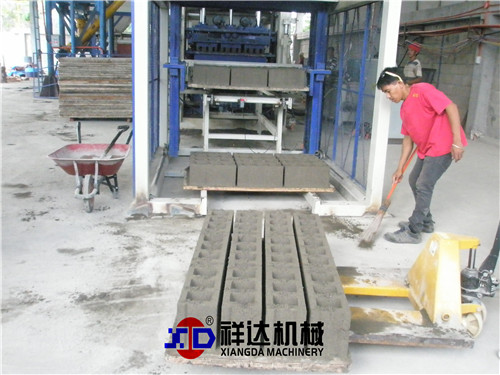

Block making machine XD12-15 is fully automatic vibrating force block machine.This block machine uses the European advanced flat vibration manufacturing technique for reference, with the lower power; it realizes the super strong vibration effect, mixing every material effectively. And the upper mould vibration compression makes the brick with average density and high strength, as well as the large-scale equipment.

Technical Parameters

BLOCK MAKING MACHINE

|

Dimension

|

2860*2340*2800mm

|

|

Vibrating style

|

Table mould vibration

|

|

Vibration frequency

|

50-70Hz

|

|

Rating pressure

|

20Mpa

|

|

Pallet size

|

1350*900mm

|

|

Cycle time

|

15-20s

|

|

Power

|

36 Kw

|

|

Weight

|

12800 kg

|

Capacity

BLOCK MAKING MACHINE

|

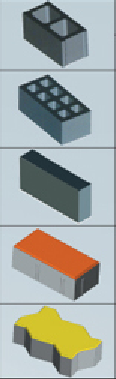

Name & picture

|

Size

|

PCS/MOULD

|

PCS/HOUR

|

|

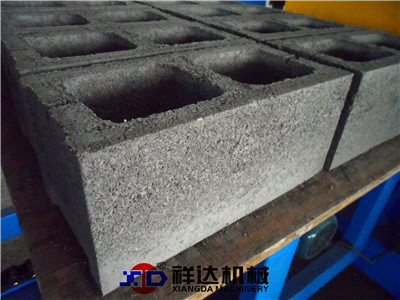

Hollow block

|

|

400*200*200mm

|

12

|

2160

|

|

Porous block

|

240*115*90mm

|

30

|

5400

|

|

Solid brick

|

240*115*53mm

|

60

|

10800

|

|

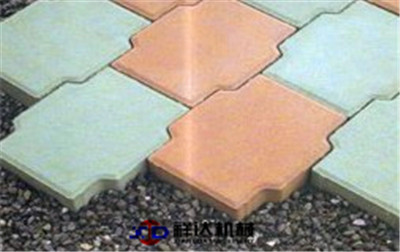

Holland brick

|

200*100*60mm

|

44

|

6600

|

|

Paving block

|

225*112.5*60mm

|

30

|

4500

|

Feature and Advantage

BLOCK MAKING MACHINE

|

|

12-15 used double swing arms structure. It will have much quickly feeding speed and more stable. Other smaller model used single hydraulic push arms.

|

|

We used the Rubber pad (PU) under the Shaking box, Can reduce the noise when the machine working. More Stably.

|

|

|

We used the Rubber pad (PU) under the Shaking box, Can reduce the noise when the machine working. More Stably.

|

|

Our control system could control easily and PLC intelligent control during the whole process. Have the overload alarm system, Make sure the safety and stability

|

|

Product application scenarios

BLOCK MAKING MACHINE

Packaging & Shipping

Packaging:standard Container, Nude Packs or in Bulk.The electrical motor or spare parts will be packed by wooden case or steel frame.Unique offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. Unique workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment.

Shipping:we deliver the cargo to China's main sea ports,like Xiamen port.And then the container will be transported to your country by sea.

Standard export packing, Spare parts are packed with wooden case, the large machines are loaded in container with nude packing, covered with plastic cloth. We export through Xiamen Port, also can be nominated by customer. We have superior cargo agent to arrange the sea shipment for each client with competitive price and secure transportation.

Cooperative customer situation

FAQ

1.How to cure the wet block?

One) Natural withering ;

Two) Steam curing at a certain temperature and humidity in the curing room;

Three) Naturally air-dried in curing room.

2. What is the strength of the brick in addition to the material of the aggregate?

a) the amount and label of cement;

b) the magnitude of the excitation force and the vibration time of the brick machine;

c) curing methods and curing time;

3.What is the life time of the mould?

Our moulds are all heat treated and carburized, with higher hardness and strength. The general life of the mould can reach 9 million times press, but it is also closely related to customer maintenance.

4. What is the control system for fully automatic production line?

There are two control panels with one power cabinet for one fully automatic line , there are many component adopts Panasonic, so we will offer one control room to prevent component from dust .

5.How many days for the natural curing of the block?

Usually , the fresh block need one night for inside curing, after that, transfer block out do water curring, it need 5-7days .

About Us

Quanzhou Xiangda Machinery Manufacture Co., Ltd. is a professional high-tech enterprise for concrete block making, owning R&D,

manufacturing,sale and after-sale service.Xiangda Corporation is established in the beginning of 1990s,

which is located in Quanzhou City, near to Xiamen Port, china. During over20 years,

we have been developing fast and getting more and more powerful with continous tech innovation and China patents.

Our main products as flws:concrete block machine. Composite insulation wall panel machine, Permeable brick production line,

Automatic palletizing system, paving block and curbstone machine, mixer batching plant and other construction machinery.

*We strictly obey the latest standard in block making industry.

*We have passed QM ISO9001:2000 and CE. Our products are popular for its stable quality and high tech.