Customize all special designs of steel roof sheet double layers, three layers roll forming machines.

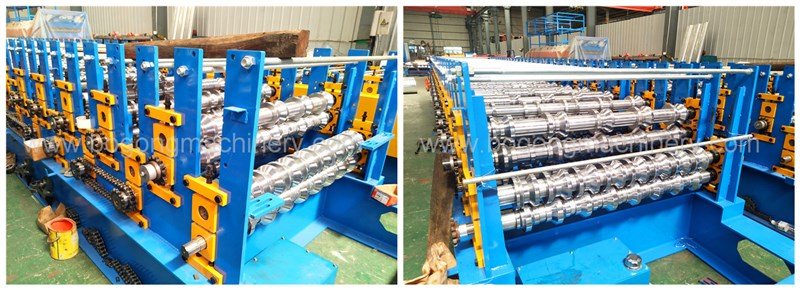

Product name: Custom Manufacture Three Layers Roof Panel Roll Forming Machine

Machine Details

This Custom Manufacture Three Layers Roof Panel Roll Forming Machine has three working layers, each layers has their own feeding table, and each feeding table also has their own hand wheels for adjusting feeding width. So each layers has alone working height, it is good for machine maintenance and adjustment.

The alone manual pre-shears for each roof panel layers also, one lay design is total separated from others.

The Custom Manufacture Three Layers Roof Panel Roll Forming Machine is installing and adjusting in our site. Install and adjust the bottom layer at first, then middle layer, at last top layers, after all roof sheet sample are confirmed well, the hydraulic cutting section can be continue.

Whole Custom Manufacture Three Layers Roof Panel Roll Forming Machine forming rollers and shafts are CNC lathe, all the rollers are coated by Chrome, good for anti-rust.

Technical Specification

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH/or customized

|

|

Driving Motor

|

11KW*3

|

|

Forming Steps

|

14 steps for upper layer, 16 steps for middle layer, 17 steps for bottom layer

|

|

Working Speed

|

18-20m/min

|

|

Thickness for Steel

|

0.4-0.6mm (Material:PPGI,GI Steel G550)

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post cutting, no waste cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

11500*1450*1650mm

|

|

Weight

|

11000KGS

|