External circulation vacuum Emulsifying mixer

Customized And OEM Service Available

Product description:

It mainly refers to the material in a vacuum state, and then vacuum Emulsifier machine using a high shear emulsifier to quickly and evenly distribute one phase or multiple phases in another continuous phase. It uses the strong kinetic energy brought by the machine to make the material in the narrow gap of the stator and rotor,and finally get free of fine and stable high quality products.

Main composition system

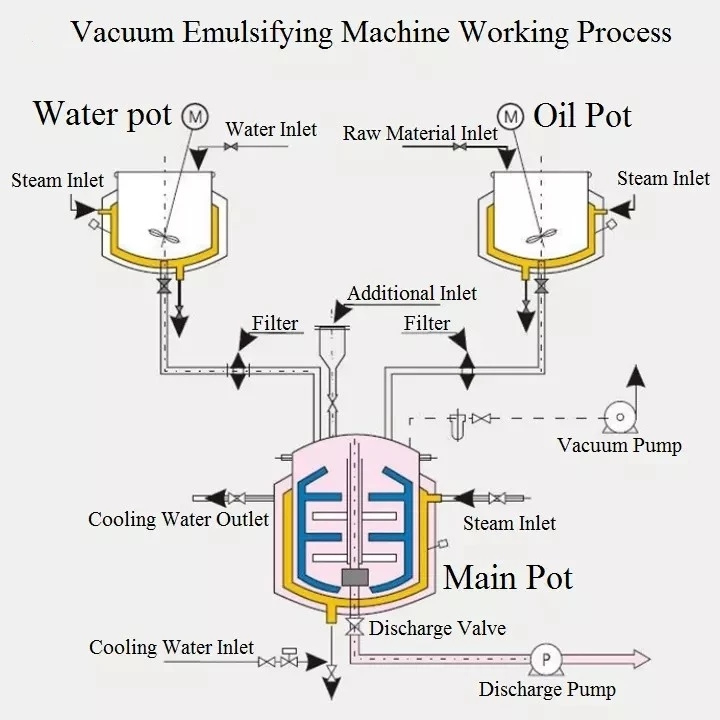

The vacuum emulsifier is mainly composed of water phase pot, oil phase pot, emulsified and stirring main pot, vacuum system, lift system (optional), electrical control system (PLC), operation platform and so on.

Working process

Application and application fields

The product is mainly used for daily care products, biomedicine, food industry, paint ink, nano material, petrochemical, printing and dyeing auxiliaries, paper industry, pesticide and chemical fertilizer, plastic rubber, electric power electronics, other fine chemicals, especially for material with large matrix viscosity and high solid content ratio.

Vacuum Emulsifying mixer is suitable for the production of various kinds of paste, cream products in cosmetic factory and pharmaceutical factory.

Technical Parameters:

|

Model

|

MZH-100L

|

MZH-500L

|

|

Main Boiler

|

117L

|

520L

|

|

Water Tank Volume

|

90L

|

480L

|

|

Oil Tank Volume

|

70L

|

400L

|

|

Main Boiler Jacket Material &

Thickness

|

Inside:316L(5mm) Mid:304(5mm)

Outside:304(3mm)

|

|

Water Tank Volume & Thickness

|

Inside:316L(3mm) Mid:304(3mm)

Outside:304(2mm)

|

|

Oil Tank Power Volume & Thickness

|

|

|

Blender Material & Thickness

|

SUS316L(thickness : 6mm)

|

|

Platform Material & Thickness

|

304(thickness : 4mm)

|

|

Safty Guardrail Material & Thickness

|

304(thickness: 1.5mm round pipe)

|

|

Speed of Scraping Plate Blender

|

0-83r/min

|

|

Speed of Homogenizer

|

0-3040 r/min

|

|

Temperature of Emulsifying Pot

|

≤180 ℃

|

|

Blender Motor

|

0.75KW

|

1.1KW

|

|

Homogenizer Power

|

3KW

|

4KW

|

|

Water Tank Power

|

0.37KW

|

0.37KW

|

|

Oil Tank Power

|

0.37KW

|

0.37KW

|

|

Vacuum Pump Power

|

0.75KW

|

0.75KW

|

|

Heating Pipe Power

|

3KW

|

6KW

|

|

Vacuum of Emulsifying Pot

|

-0.09Mpa

|

|

Pressure of Jacket

|

normal pressures

|

|

Voltage

|

50-60Hz 380V±10%-15%

|

|

Grass Weight

|

about 250KG

|

about 300KG

|

|

Overall Dimension

|

1.24*0.65*1.35 m

|

1.25*0.75*1.35M

|

Company overview

We are leading manufacturer in China which specialized in Cosmetic machinery, Food machinery and Pharmacy machinery products supplying for over 15 years; good quality and professional service help us gain many good reputation all over the world;

we hope you can join us in the future.

Package: Plywood Case Packing

Our Service

Our Service

Pre-Sales Service After-Sales Service

1. Inquiry and consulting support. 1. Training how to instal the machine, training how to use the

2.Sample testing support. 2. Engineers available to service machinery overseas.

3.View our Factory.

FAQ

1. Q: Are you factory or trading company?

A: We are the professional manufacture of cosmetic machinery in China more than 15years,We have our own factory and skilled workers, rich-experienced R&D and professional service team.

2. Q: Where is your location?

A: Company and Showroom located in Guangzhou china, Factory located in Jiangsu and Shanghai Province.

3. Q:How about the Product Range?

A: We can provide a wide range of products for your One-stop sourcing. Also we can customize according to your specific requirements.

4. Q: How does your factory do regarding quality control?

A: Our quality is built on good quality material, imported from Japan, Germany etc. We have passed ISO9001,CE, GMP. Our price is based on the quality, and we will give reasonable prices to every customer.

5. Q:How about the after service?

A: We can give you one years after sales warranty, we can also send our engineer to you factory to install this equipment and train your staff, but the Buyer should pay the round air ticket cost and arrange the hotel accommodation as well as the means for Seller’s engineer. We will send some free set of spare parts for you change it.

Our Company to customer satisfaction for the development of three goals: product quality, product technology and after-sales service!

Pre-Sales Service After-Sales Service

1. Inquiry and consulting support. 1. Training how to instal the machine, training how to use the

2.Sample testing support. 2. Engineers available to service machinery overseas.

3.View our Factory.

FAQ

1. Q: Are you factory or trading company?

A: We are the professional manufacture of cosmetic machinery in China more than 15years,We have our own factory and skilled workers, rich-experienced R&D and professional service team.

2. Q: Where is your location?

A: Company and Showroom located in Guangzhou china, Factory located in Jiangsu and Shanghai Province.

3. Q:How about the Product Range?

A: We can provide a wide range of products for your One-stop sourcing. Also we can customize according to your specific requirements.

4. Q: How does your factory do regarding quality control?

A: Our quality is built on good quality material, imported from Japan, Germany etc. We have passed ISO9001,CE, GMP. Our price is based on the quality, and we will give reasonable prices to every customer.

5. Q:How about the after service?

A: We can give you one years after sales warranty, we can also send our engineer to you factory to install this equipment and train your staff, but the Buyer should pay the round air ticket cost and arrange the hotel accommodation as well as the means for Seller’s engineer. We will send some free set of spare parts for you change it.

Our Company to customer satisfaction for the development of three goals: product quality, product technology and after-sales service!