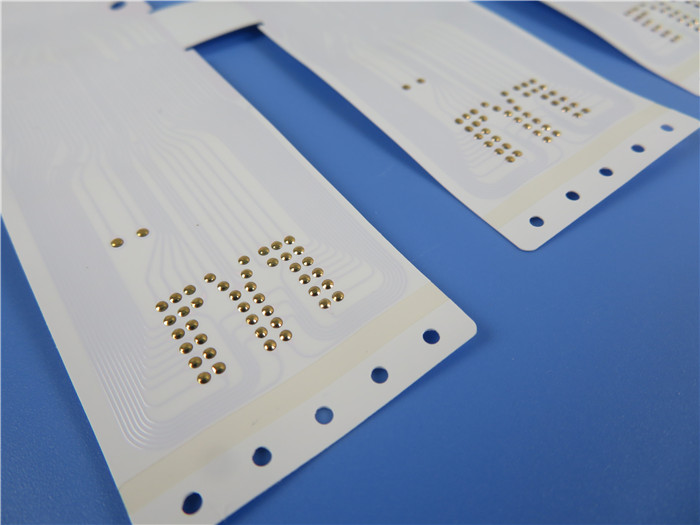

Flexible Printed Circuit FPC on PET with

White Solder Mask

(Flexible

printed circuits are custom-made products, the picture and parameters shown are

just for reference)

General Information:

The FPC is coating with

white solder mask and immersion gold on pads. The pads are bulged for the

printer applications.

FPC Specifications:

|

PCB SIZE

|

172 x

145mm=1PCS

|

|

Base Material:

|

PET

|

|

Number of Layers

|

Double sided PCB

|

|

SMT

|

n/a

|

|

Through Hole Components

|

no

|

|

LAYER STACKUP

|

Copper

------- 35um(1oz)

|

|

Adhesive

|

|

PET

|

|

Adhesive

|

|

Copper ------- 35um(1oz)

|

|

Minimum Trace and Space:

|

4mil/8mil

|

|

Minimum / Maximum Holes:

|

1.2mm/

3.5mm

|

|

Final foil external:

|

1oz

|

|

Final foil internal:

|

0oz

|

|

Final height of PCB:

|

0.25mm

±0.05

|

|

Surface Finish

|

Immersion

gold

|

|

Solder Mask Apply To:

|

TOP, Bottom

|

|

Solder Mask Color:

|

White Coverlay

|

|

CONTOUR/CUTTING

|

Punching

|

|

Stiffener:

|

PET

on back of gold finger area

|

|

Side of Component Legend

|

NO

|

|

Colour of Component Legend

|

NO

|

|

VIA

|

Plated

Through Hole(PTH)

|

|

FLAMIBILITY RATING

|

UL

94-V0 Approval MIN.

|

|

TEST

|

100%

Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email

file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide,

Globally.

|

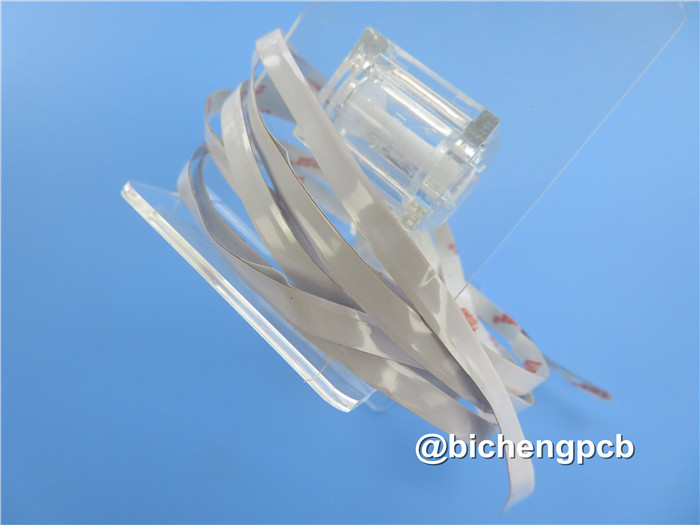

Features and Benefits:

Excellent flexibility;

Reduced PCB volume;

Reduced weight;

Increased reliability

Consistency of assembly;

More than 18+ years of PCB experience;

Customer complaint rate: <1%

Prototype capability;

Volume Production capability

Typical Applications:

Capacitive

touch screen / panel, Industrial control temperature controller soft board,

consumer card reader soft board

Covercoat

/ Solder Mask:

Solder

mask in flexible PCB is different from rigid board, it is usually a polyimide

film coated on one side with a semi-cured and non-tacky adhesive, we call it

covercoat in flexible circuit. It is laminated to the flexible circuit under

heat and pressure, so that the copper pattern is fully encapsulated except for

the solder pads that are exposed through access holes in the covercoat.

The

covercoat production sheet should be cut slightly smaller than the flexible

circuit production sheet to avoid premature edge sealing, which could trap air

bubbles in the package.

The

production sheet for the covercoat is provided with tooling holes in close

register with the tooling holes in the production sheet for the flexible

circuit. The access holes are usually drilled, but in the case of high-volume

production, punching is more cost-effective.

In

principle, drilling of the covercoat is accomplished in the same way as when

drilling rigid boards, i.e., a number of covercoat sheets are stacked, either

5-up or 10-up. The drilling parameters, however, are somewhat different,

because of the polyimide material and the absence of copper foil, which otherwise

could have removed some of the heat from the holes being drilled.

When

drilling/punching large covercoat production sheets, it is necessary to

compensate for the dimensional changes of the flexible circuit production

sheet, which can amount to as much as 0.2%.

FPC Capabilities 2022:

|

No.

|

Specifications

|

Capabilities

|

|

1

|

Board

Type

|

Single

layer, Doulbe layer, Multilayer, Rigid-Flex

|

|

2

|

Base

Material

|

PI,

PET

|

|

3

|

Copper

Weight

|

0.5oz,

1oz, 2oz

|

|

4

|

LED

Maximum Size

|

250

x 5000mm

|

|

5

|

General

Maximum Size

|

250

x 2000mm

|

|

6

|

Board

Thickness

|

0.03mm-3.0mm

|

|

7

|

Thickness

Tolerance

|

±0.03mm

|

|

8

|

Mininum

Drill Hole

|

0.05mm

|

|

9

|

Maximum

Drill Hole

|

6.5mm

|

|

10

|

Tolerance

of Drill Hole

|

±0.025mm

|

|

11

|

Thickness

of Hole Wall

|

≧8 um

|

|

12

|

Minimum

Track/Gap of Single Layer Board

|

0.025/0.03mm

|

|

13

|

Minimum

Track/Gap of Double Layer and Multilayer Board

|

0.03/0.040mm

|

|

14

|

Etching

Tolerance

|

±0.02mm

|

|

15

|

Minimum

Width of Silk Legend

|

≧0.125mm

|

|

16

|

Minimum

Heigh of Silk Legend

|

≧0.75mm

|

|

17

|

Distance

from Legend to Pad

|

≧0.15mm

|

|

18

|

Distance

from Opening Solder Mask of Drill Coverlay to Track

|

≧0.03mm

|

|

19

|

Distance

from Opening Solder Mask of Punching Coverlay to Track

|

≧0.03mm

|

|

20

|

Thickness

of Immersion Nickel

|

100-300u"

|

|

21

|

Thickness

of Immersion Gold

|

1-3u"

|

|

22

|

Thicnkess

of Immersion Tin

|

150-400u"

|

|

23

|

Minimum

Electrical Testing Pad

|

0.2mm

|

|

24

|

Minimum

Tolerance of Outline(Normal Steel Mould Punch)

|

±0.1mm

|

|

25

|

Minimum

Tolerance of Outline (Precision Steel Mould Punch)

|

±0.05mm

|

|

26

|

Mininum

Radius of Bevel Angle (Outline)

|

0.2mm

|

|

27

|

Stiffner

Material

|

PI,

FR-4, 3M Adhesive, PET, Steel Sheet

|

|

28

|

RoHs

|

Yes

|

|

29

|

Solder

Mask Colour

|

Yellow,

White, Black, Green

|

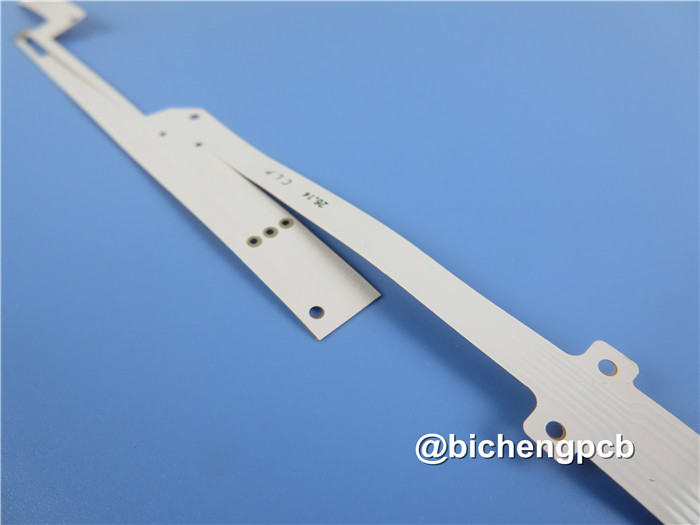

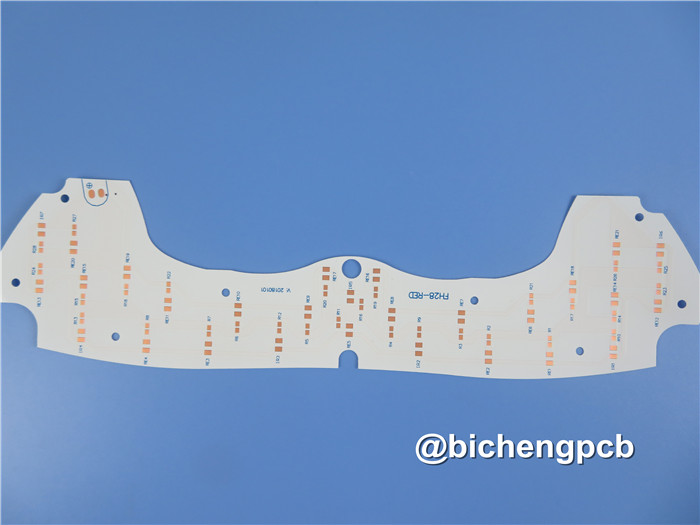

More

Displays of White Flex:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS: