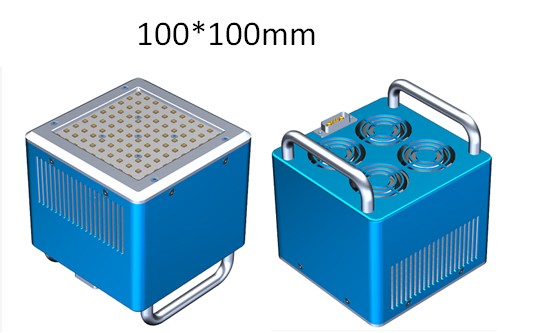

Factory Direct Sales, 100*100mm UV LED Surface Light Source uses Korean original factory imported UV LED UV Light Beads, curing UV glue and UV ink, quality guranteed.

Controller specification of Customized 405nm UV Drying Machine for Epoxy Resin :

|

shape

|

L320*W130*H130mm

|

weight

|

2.7kg

|

|

cool down

|

Air cooled

|

Input power

|

100-240V AC 50-60 HZ

|

|

material

|

Blue paint

|

Number of driving heads

|

One

|

|

RS232 serial communication

|

Can query and adjust intensity, time, mode

|

Display and operation

|

Touch screen for adjustable time and intensity

|

|

LED time accumulation

|

Active record cumulative usage time

|

External terminal block

|

Can be connected with single-chip, PLC and other equipment for control and working status feedback

|

Rectangular Irradiation head specifications of Newest 100*100mm 405nm UV LED Area Light Source Curing UV Coating :

|

Light size

|

100 * 100mm

|

power

|

300W

|

|

Dimensions

|

L 130*W130*H112 mm

|

Recommended height

|

5 mm

|

|

cool down

|

Air cooled

|

wavelength

|

365 / 385 / 395 / 405

|

|

Material / weight

|

Sheet metal / 2kg

|

Luminous power (mW/cm 2 )

|

1800

|

2000 @ EIT

|

|

Prediction of service life

|

20000 H

|

|

Monitoring method

|

temperature check

|

Cable length

|

2 / 5 m

|

100*100mm UV LED curing machine, long-term stock inventory, can be shipped the same day. For other sizes of Customized 405nm UV Light Source Solidify UV Ink, please contact customer service or directly contact Jennifer : +86-18924372460.

Product Advantages of High Quality LED Ultraviolet Ink Curing Machine:

Single wavelength UV output with no harmful thermal effects

The high-power LED radiation single-wavelength light source is highly targeted and efficient. Eliminates the effects of source radiation other than the dominant wavelength. In particular, it does not contain infrared rays, which greatly reduces the thermal impact on the workpiece. It is the ideal source for high-precision curing that is very sensitive to thermal effects. For example, the assembly of an ultra-thin resin lens.

Low power consumption, saving energy

A low power consumption equivalent to only a few tenths of a UV mercury lamp is achieved. Products can significantly reduce energy consumption and waste emissions every year. Reduce environmental load.

Free layout and space saving

With UV-LED, the volume is reduced by about 90% compared to the UV mercury lamp. The weight is also greatly reduced, no need to worry about the installation space, and the layout is more free.

The head can be controlled separately or at the same time, saving equipment investment

According to the need to select the number of illumination heads, multiple conventional UV mercury light sources can now be replaced by a UVLED line or a surface light source. Reduce equipment investment, while the head can be controlled individually or in conjunction according to on-site process requirements.

Stable output accuracy

The unique heat dissipation technology in the UV-LED field creates a cooling method that combines high light quantity and long life to minimize drift and achieve stable illumination.

Long life and reduced operating costs

Compared with UV mercury lamps, the life of LED lamps is greatly extended. This is the characteristic of LED. Unlike UV mercury lamps, which can only be brightly lit, UVLEDs can be turned off instantly, so the actual life span is even greater.

Wide range of uniform illumination

With a unique optical system, UV illumination that minimizes variations in light amount over a wide range is achieved. It can inhibit curing and drying spots and curing deformation of adhesives, and assist customers in quality management.

The installation dimensions in the figure below are detailed in the specifications at the time of shipment.The shipping date shall prevail.

Detailed application areas UVLED surface light source 100*100mm is used in the following industries.

Application of UV-LED Light Source to UV oil/UV adhesive/UV coating

1. UV light curing silk screen varnish can be used for printing partial glazing, or full glazing, glazing printing surface is bright and transparent, with photo effect, wear resistance, no layer, no curl, use Surface decoration and protection of high-grade packaging.

Features:

a. The product is odorless, contains no toner, has little skin irritation and fast curing speed.

b. The product has excellent defoaming and leveling properties and can be adapted to the fast printing of automatic printing presses.

c. The product has excellent adhesion and folding resistance to gold and silver paper.

d. The product viscosity can be adjusted to different mesh screens, and can be widely printed wine boxes and cigarette boxes.

2. UV plastic varnish (hot stamping) is mainly used for the coating of PE, PP film or sheet surface, suitable for toothpaste tube, PE hose and film self-adhesive surface glazing.

Features : yellowing resistance, low odor, abrasion resistance, high gloss, good flexibility. This series also has UV matte varnish.

3. CD protection UV varnish disc protection glue is the key material for the production of optical discs. It is very important for the quality of optical discs. It needs to be bonded to the reflective metal layer of the disc. It has strong adaptability to ink, good high and low temperature performance, and resistance. Excellent wear and tear, the company's Shenzhen Deshengxing technology products have the above characteristics.

4. UV light curing adhesive

Features: One-component UV light curing adhesive, UV light curing adhesive, not only convenient to use than traditional two-component heat curing adhesive. And has the following characteristics.

Optical properties: the plastic liquid crystal is transparent, and the light transmittance after curing is ≥90%.

Bonding performance: The volume shrinkage after curing is small, the elongation is large, and the bonding strength is high.

Weather resistance: After the glue is cured, it has good weather resistance. It is not yellow when exposed to ultraviolet light for a long time. It has strong heat and cold resistance and can be used in the temperature range of minus 50 degrees to 80 degrees Celsius.

Uses: For transparent materials such as: transparent plastic, glass and metal, plastic, ceramic, rubber and other non-transparent materials for fast bonding, bonding curing time can be as fast as 1 second, bonding strength can be adjusted, suitable for optical discs, electronics Bonding or mounting of devices, optical communication devices, biological products, furniture, etc.

a. UV disc adhesive: UV disc glue, suitable for the production of DVD5/DVD10.

b. Glass-aluminum alloy adhesive (UV light curing shadowless adhesive): can be widely used in optical instruments, medical devices, handicrafts, furniture and construction industries, glass/metal, glass/glass, metal/metal, etc. Bonding.

Usage: first clean the surface of the sticky material, dry it, drop a small amount of glue on the surface of the adherend, press the surface to discharge the bubbles in the adhesive layer, make the thickness of the adhesive layer less than 25μm, and use high-pressure mercury lamp after sizing (power- 60W/CM) curing at 10CM lamp distance for 10-20 seconds (the curing time is slightly different depending on the light-transmitting material and the lamp. After half an hour, the performance of the shadowless glue is optimal.

5. UV curing soft rubber

Uses: Transparency of trademarks, badges, labels, etc.

Features: The liquid glue is stable in storage and quickly solidifies upon exposure to ultraviolet light. The cured adhesive is transparent, elastic, scratch resistant, and the indentation and scratches can disappear on their own.

Usage: After the glue is applied, it can be sent to the photocuring oven for curing. The thickness of the adhesive layer is not more than 2mm. The curing conditions are: high pressure mercury lamp, 60-80M/CM, curing time 10-25 seconds.

Customized UV LED Area light source in smartphone applications

1 , mobile phone screen with adhesive border phone 2 , phone housing an adhesive 3 , the side key adhesively fixed 4 , the camera positioning of the window . 5 , LOGO paste 6 , smart machines sound chamber with a lid of the cartridge 7 , smart phones FPC between the antenna and the housing 8 , the camera module in HOLDER and FPC between ( FPC bending region) 9 , the phone connection is fixed flat motor . 10 , the fixed phone board

Medical device LED Ultraviolet Curing Light curing application

UV glue bonding makes economical automated assembly of medical devices easier. Nowadays , the advancedLED UV light source system , which can cure solvent-free UV glue for a few seconds , as well as the dispensing system , makes an effective and economical method for consistent and repetitive bonding of medical device assembly processes. The optimization and control of UV light sources is very important for the manufacture of reliable medical devices. The use of UV-curable glue offers many advantages , such as lower energy requirements , saving cure time and location , increasing productivity and making automation easier. UV glue is commonly used to bond and seal medical devices that require very high quality and best reliability. UV glue curing Typical applications are in the medical device assembly , such as the need bond 1) of different material ( or different mechanical properties ) 2) material is not thick enough , can not use the soldering method 3 ) pre-production of sub-parts. .

1 , anesthesia mask 2 , syringe 3 , catheter 4 , intravenous infusion tube 5 , vascular implant accessories 6 . Endoscope 7 , arterial positioning 8 , tubular drainage device 9 , tracheal tube 10 , blood oxygenator 11 , hearing aid 12 , detection , monitoring , and imaging equipment 13 , biochip 14 , bonding PVC, thermoplastic ( polycarbonate) Fat and ABS)

Optical communication industry UV LED light curing application

1 . Passive components (wavelength division multiplexer WDM, array grating waveguide AWG, optical splitter SPLITTER, optical isolator ISOLATOR, optical coupler COUPLOR, etc.) , various glass package structure bonding or potting , fixing of small components Wait.

2 . Active devices (coaxial devices TOSA/ROSA/BOSA, VCSEL , laser collimators, etc.), especially FTTX low-cost miniaturized plastic package structures

3 . Fiber optic cable (overcoat , marking , bonding, fiber optic gyroscope)

Research and Institute - ST-UV LED Light Curing Application

1. Polymer chemistry ( nano coating , photocurable resin , photosensitizer , monomer , UV ink, etc. )

2 , medical polymer materials ( medical plastics , catheters ), microorganisms

3 , photochemistry ( photocatalysis , photoexcitation , photosynthesis, etc. )

4 , semiconductor ( light accelerated etching , cutting , uv tape, etc. )

FPC surface protection adhesive curing UV LED line source features:

1 : cold light source, no heat radiation, especially suitable for liquid crystal edge sealing, film printing requires a small temperature rise area for use.

2 : Instantly illuminate, instantly achieve 100% power UV output, and the irradiation intensity can reach8000-9000mW/cm2.

3 : Small size - makes the equipment easy to integrate into fully automatic production lines and equipment.

4 : It does not use toxic substances and does not produce ozone. It is a safer and more environmentally friendly alternative to traditional light sources.