Large

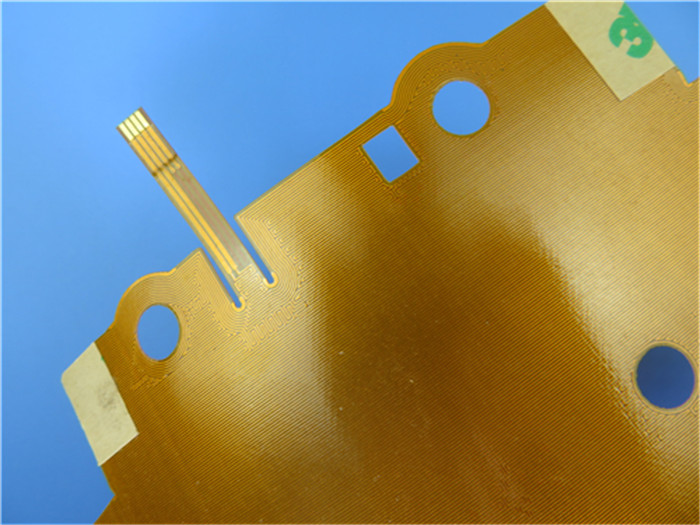

Flexible Circuits Fine Line FPC With Coil Design

(FPC’s

are custom-made products, the picture and parameters shown are just for

reference)

General

description:

It’s a 2 layer board at 0.15mm thick. The

base laminate is from Shengyi. It’s fabricated per IPC 6012 Class 2 using

supplied Gerber data. Polyimide stiffener is applied on the inserting part.

Parameter

and data sheet:

|

Number

of Layers

|

2

|

|

Board Size

|

160

x 165mm=1PCS

|

|

Board Type

|

Flexbile

cirucit

|

|

Board Thickness

|

0.15mm

+/-10%

|

|

Board Material

|

Polyimide

(PI) 25um

|

|

Board Material Supplier

|

ITEQ

|

|

Tg Value of Board Material

|

60℃

|

|

|

|

PTH Cu thickness

|

≥20 um

|

|

Inner Iayer Cu thicknes

|

N/A

|

|

Surface Cu thickness

|

35

um (1oz)

|

|

|

|

Coverlay Colour

|

Yellow

|

|

Number of Coverlay

|

2

|

|

Thickness of Coverlay

|

25

um

|

|

Stiffener

|

NO

|

|

|

|

Type of Silkscreen Ink

|

NO

|

|

Supplier of Silkscreen

|

NO

|

|

Color of Silkscreen

|

NO

|

|

Number of Silkscreen

|

NO

|

|

|

|

Mininum Trace (mil)

|

4

mil

|

|

Minimum Gap(mil)

|

4

mil

|

|

|

|

Surface Finish

|

Immersion

Gold

|

|

RoHS Required

|

Yes

|

|

Famability

|

94-V0

|

|

|

|

Thermal Shock Test

|

Pass, -25℃±125℃, 1000 cycles.

|

|

Thermal Stress

|

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering.

|

|

Function

|

100%

Pass electrical test

|

|

Workmanship

|

Compliance

with IPC-A-600H & IPC-6013C Class 2

|

Features

and benefits:

Excellent

flexibility

Reducing

the volume

Weight

reduction

Consistency

of assembly

Increased

reliability

The

end can be whole soldered

Low

cost

Continuity

of processing

Quick

and on-time delivery

Make

delivery on time. We keep higher than 98% on-time-delivery rate.

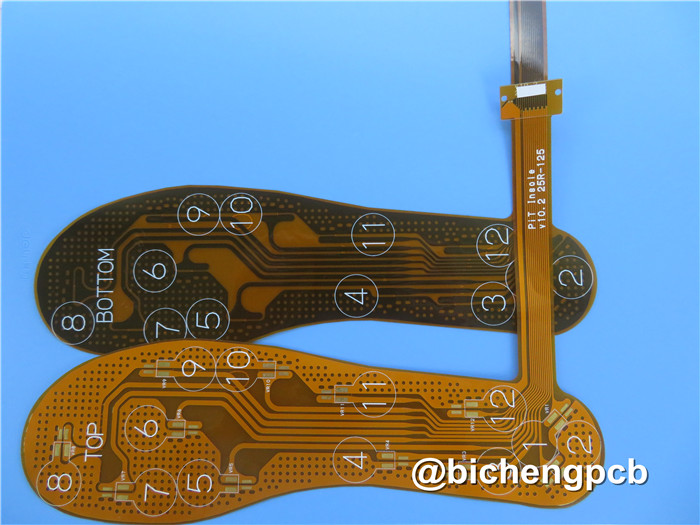

Applications:

Keypad

FPC, Industrial control computer soft board, consumer ETC (Electronic Toll

Collection ) soft board,

Basic

Types of Flexible Circuit:

There

are five basic types of flexible circuits as described below:

1.

Single-Sided Flexible Circuits

This

is the simplest type, and consists of a thin and flexible base material to

which a copper foil is laminated by means of an adhesive. The finished circuit

is frequently provided with a covercoat bonded to the copper side by means of

an adhesive.

2.

Double-Sided Flexible Circuits

As

the name suggests, the circuit consists of a thin and flexible base material

with copper foil laminated to each side. The outer sides of the finished

circuits are frequently provided with covercoats bonded to the outer sides

(copper).

3.

Multilayer Flexible Circuits

A

multilayer flexible circuit consists of a number of thin and flexible base

laminates and copper foils laminated together by means of adhesive, in very

much the same way as rigid multilayer boards. Also it is common practice to

bond covercoats to the outer sides (copper).

4.

Flex-Rigid Circuits

A

flex-rigid circuit is a combination of rigid boards and flexible circuits, the

latter creating flexible interconnects between the rigid boards to which they

are laminated by means of bond plies.

5.

Flexible Circuits with Rigid Areas

In

some cases, the flexible circuit must support a number of relatively heavy

components or even a connector part. Therefore it is necessary to reinforce

such an area. This is accomplished by bonding a stiffener to that area. The

stiffener can be an extra layer of not too thin polyimide, or it can be a

glass/epoxy laminate.

More

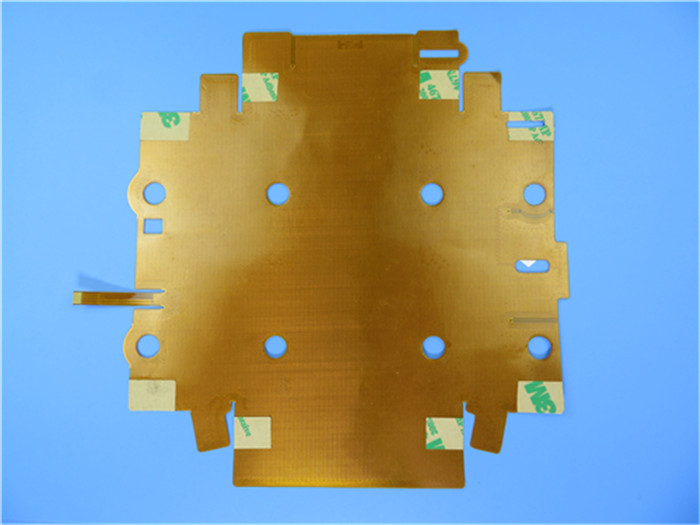

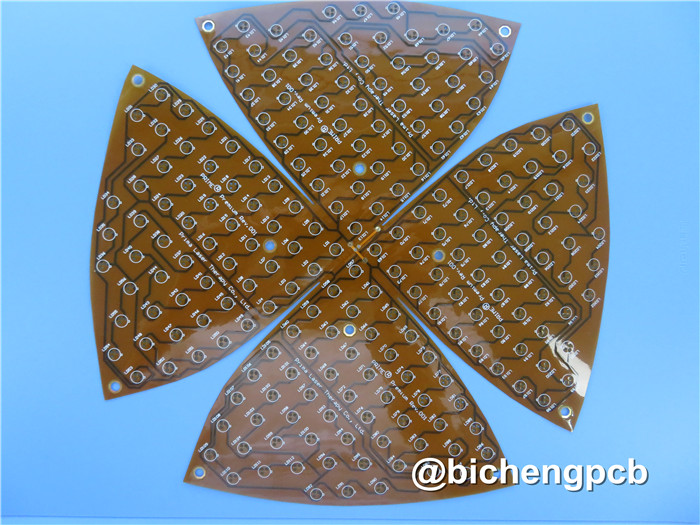

Displays of Large Flexible Circuits

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS: