Overview

Optical‑Electrical Composite Cables integrate optical fibers and power conductors within a single cable to simultaneously deliver data and electrical power. This one‑cable solution streamlines deployment, reduces conduit occupancy, and lowers total installation cost. Typical designs adopt XLPE or EPR insulation for the power cores, comprehensive water‑blocking, and robust strength/armour options for harsh environments. The optical unit can be loose‑tube single‑mode fibers or ribbon fibers, protected by metallic or all‑dielectric strength members depending on application and EMC requirements.

Typical power voltage ratings: 0.6/1 kV, 1.8/3 kV, 3.6/6 kV, 6/10 kV (custom higher ratings on request)

Power conductors: Copper or aluminum, round/sector, compacted

Power insulation: XLPE (typical), EPR optional

Optical fibers: G.652D/G.657A1/A2 single‑mode (others on request; ribbon optional)

Shielding (power cores): Conductor/insulation semi‑conductive screens + metallic screen (Cu wires/tape) as required by voltage class

Mechanical protection: Steel tape armour (STA) or steel wire armour (SWA); all‑dielectric options available for high‑EMI areas

Outer sheath: PVC, PE, or LSZH; anti‑tracking jackets for aerial/ADSS‑like scenarios optional

Water‑blocking: Water‑blocking tape/gel; longitudinal and/or radial designs

Applications: 5G/telecom sites, smart security, industrial automation, surveillance poles, tunnels, campus/park distribution, remote power‑communication integration

Standards: IEC 60502 (power components), IEC 60794 (optical components), GB/T 12706, YD/T (where applicable), ICEA/IEEE (customizable compliance)

Key Features

One‑cable integration of power and fiber: simplifies routing, reduces installation time and CAPEX

High electrical reliability: XLPE/EPR insulation with robust screening to control partial discharge (per voltage class)

High optical performance: low‑attenuation single‑mode fibers with excellent bending performance (G.657A1/A2 optional)

Comprehensive water‑blocking and optional armour for direct burial and rugged environments

Fire‑safety options: flame‑retardant and LSZH sheaths for indoor or public‑area compliance

Flexible EMC design: all‑dielectric or metallic armour/screening tailored to site conditions

Suitable for multiple installations: trays, ducts, poles, direct burial, and tunnels

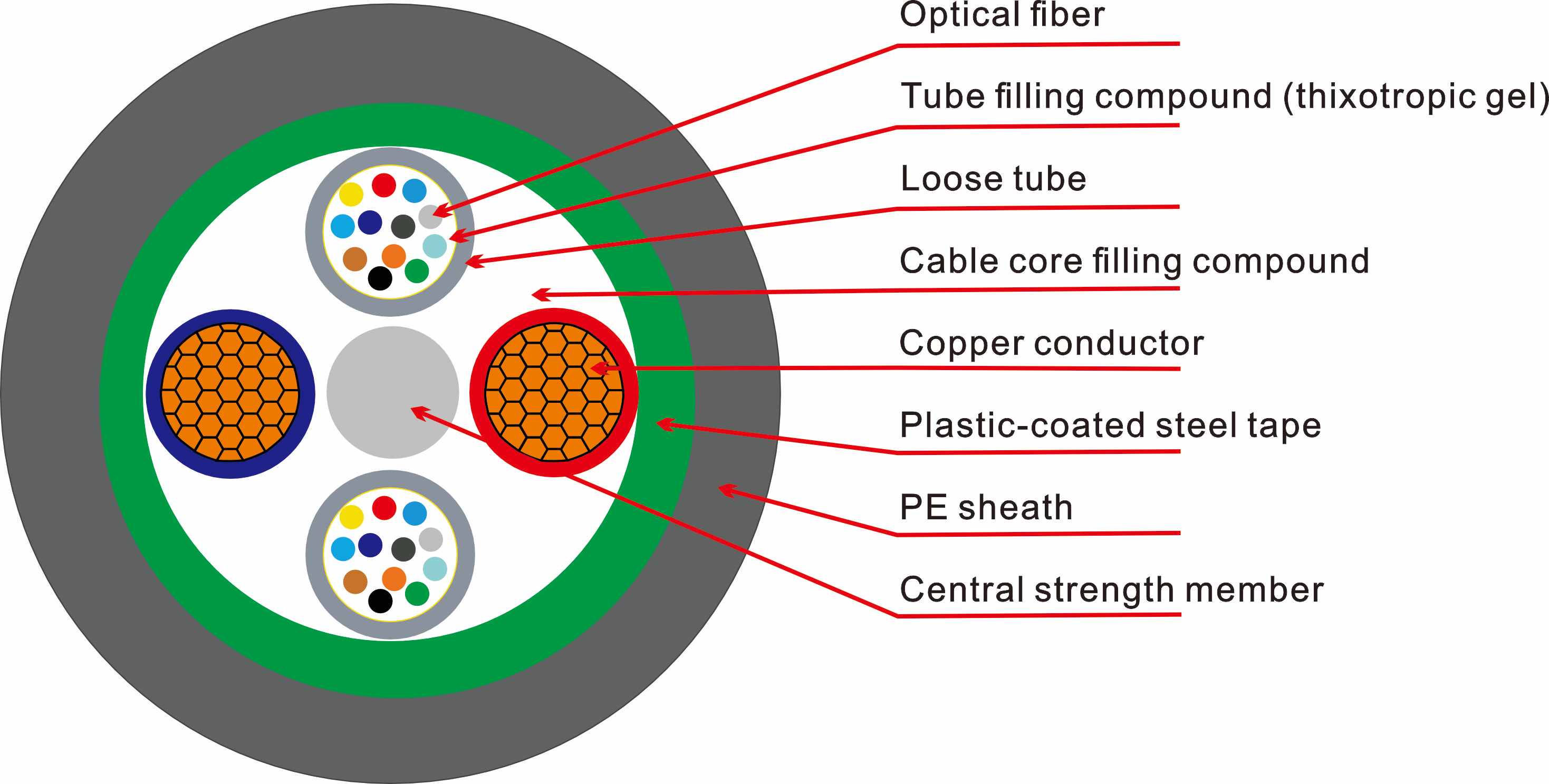

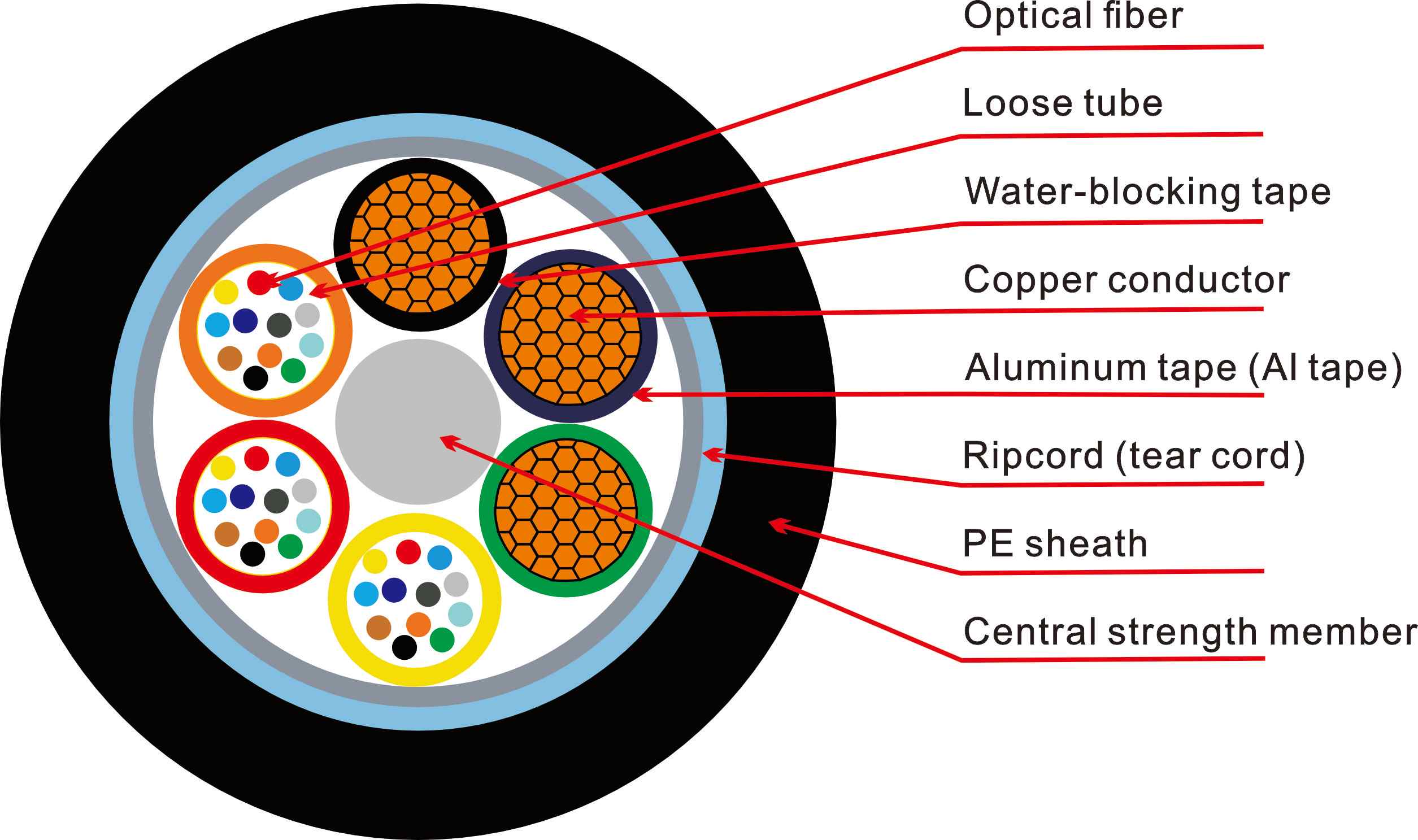

Layered from inside to outside

Factory photos

If you need technical support, please feel free to contact us.

Customization & Technical Support

• E-Mail: overseasales@tiankang.com

Sales Support:

• E-Mail: overseasales01@tiankanginternational.com