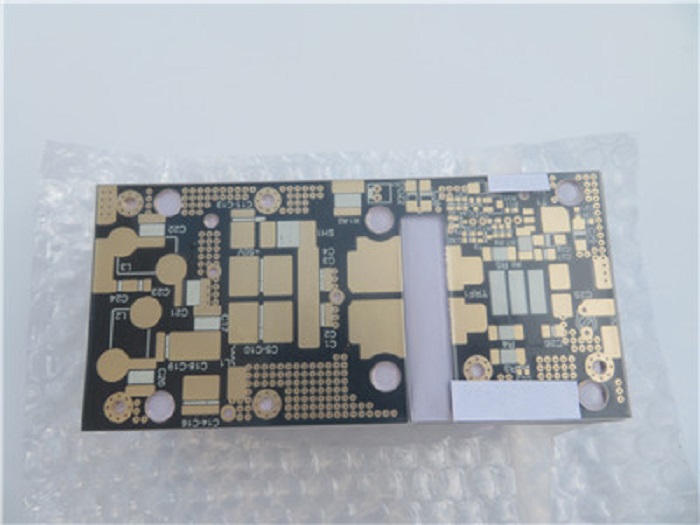

PTFE High Frequency PCB on DK2.65 F4B

0.8mm 1oz Copper With Immersion Gold and Black Solder Mask

Used as

engineering plastic, it can be made into PTFE tube, rod, belt, plate, film and

so on. Generally it’s used in high performance requirements of

corrosion-resistant pipes, containers, pumps, valves as well as radar,

high-frequency communication equipment, radio equipment.

Excellent performance:

1)high temperature resistance: long-term use temperature

200~260 degrees Celsius.

2)low temperature resistance: still soft at -100 degrees

Celsius;

3)corrosion resistance: resistant aqua regia and all organic

solvents;

4)climate resistance: best aging life in plastics;

5)high lubrication: with the smallest friction coefficient in

plastics (0.04);

6)Non-viscous: with minimal surface tension in solid

materials without adhering to any substance;

7)non-toxic: with physiological inertness;

8)excellent electrical properties, ideal for C class of

insulating materials, a thick layer of stack of newspaper can block 1500 V of

high voltage;

9)smoother than ice.

F4BM-1/2 High Frequency PCB

F4BM-1/2 is laminated by laying up

of varnished glass cloth with Teflon resin,according to the scientific formulation and strict technology process. This

product takes some advantages over F4B series in the electrical performance(wider range of dielectric constant、lower dielectric loss angle tangent、increased resistance、and

more stability of performance)

At RF and Microwave frequencies, the dielectric

constant of PTFE materials is as low as 3.5 or below, which keeps strong signal

during transmission across PCB, making them ideal for overcoming the high speed

limitation of FR-4.

PCB Capability (PTFE):

|

PCB

Material:

|

Fibre glass

coated PTFE

|

|

Code:

|

F4BM-1/2 (family series)

|

|

Dielectric constant:

|

2.2, 2.55, 2.65,

|

|

|

3.0 and 3.5

|

|

Layer count:

|

1 Layer, 2 Layers and

multi-layer

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz

(35µm), 2oz (70µm), 3oz (105µm)

|

|

PCB thickness:

|

0.25mm,

0.5mm, 0.8mm, 1.0mm, 1.5mm, 2.0mm,3.0mm, 4.0mm, 5.0mm, 6.0mm, 8.0mm, 10.0mm,

12.0mm

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare copper, HASL,

ENIG, Silver, OSP,etc.

|

Data Sheet of F4B (PTFE):

|

Name

|

Test condition

|

Unit

|

Value

|

|

Density

|

Normal state

|

g/ cm3

|

2.1~2.35

|

|

Moisture

Absorption

|

Dip in the distilled

water of 20±2℃ for 24

hours

|

%

|

≤0.02

|

|

Operating

Temperature

|

High-low temperature

chamber

|

℃

|

-50℃~+260℃

|

|

Thermal

Conductivity

|

|

W/m/k

|

0.8

|

|

CTE (typical)

|

0~100℃ (εr :2.1~2.3)

|

ppm/℃

|

25(x)

|

|

34(y)

|

|

252(z)

|

|

CTE (typical)

|

0~100℃ (εr :2.3~2.9)

|

ppm/℃

|

14(x)

|

|

21(y)

|

|

173(z)

|

|

CTE (typical)

|

0~100℃ (εr :2.9~3.5)

|

ppm/℃

|

12(x)

|

|

15(y)

|

|

95(z)

|

|

Shrinkage

Factor

|

2 hours in boiling

water

|

%

|

0.0002

|

|

Surface Resistivity

|

500V DC

|

Normal state

|

M·Ω

|

≥1×104

|

|

Constant

humidity and temperature

|

≥1×103

|

|

Volume Resistivity

|

Normal state

|

MΩ.cm

|

≥1×106

|

|

Constant

humidity and temperature

|

≥1×105

|

|

Pin Resistance

|

500V DC

|

Normal state

|

MΩ

|

≥1×105

|

|

Constant humidity and temperature

|

≥1×103

|

|

Surface dielectric strength

|

Normal state

|

d=1mm(Kv/mm)

|

≥1.2

|

|

Constant

humidity and temperature

|

≥1.1

|

|

Dielectric Constant

|

10GHZ

|

εr

|

2.20,2.55,2.65,3.0,3.5 (±2%)

|

|

Dissipation Factor

|

10GHZ

|

tgδ

|

2.2

|

≤7×10-4

|

|

2.55~2.65

|

≤1×10-3

|

|

3.0~3.5

|

≤1.5×10-3

|

PCB MANUFACTURING PROCESS:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS: