PU Plastic Prototype Part for Philip Medical System

|

Export

to

|

Japan

|

|

Brand

|

Honda

|

|

Cavity number

|

1+1

|

|

Material

|

ABS

|

|

Mold life time

|

1,000,000

|

|

Computer

software

|

CAD, UG,

ProE,SolidWorks,etc.

|

|

Main service

|

Prototypes, Mold

design, Mold making, Mold tesing, low/ high volume plastic production

|

|

Raw material

|

PP,PA6,PLA,AS,ABS,PE,PC,POM,PVC,

PET,PS,TPE/TPR etc

|

|

Mold base

material

|

P20, S45C, S50C etc.

|

|

Cavity &

Core material

|

S136,718,2378,2316,4CR13,S50C,

P20, H13, NAK80 etc.

|

|

Hot runner

|

Syventive, Incoe,

Yudo, etc.

|

|

Mold standard

|

DME, HASCO, LKM, etc.

|

|

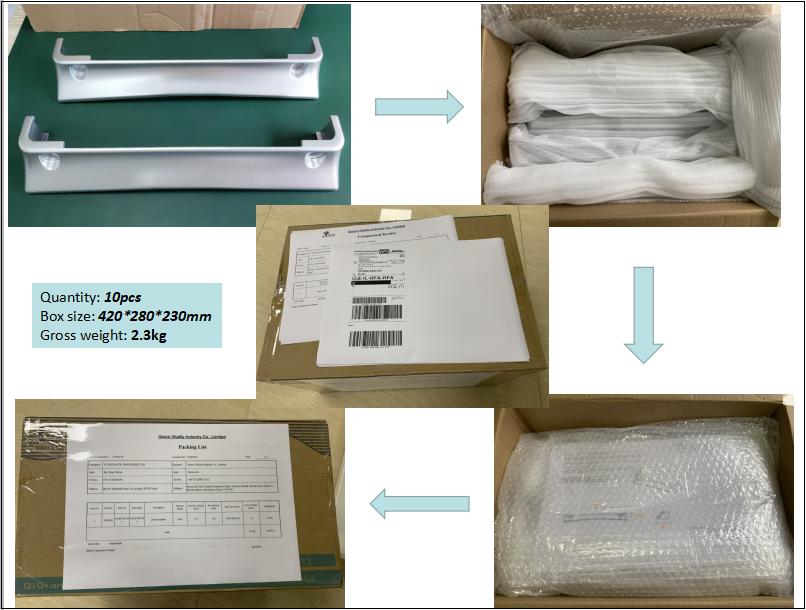

Packaging

|

Vacuum package &

plywood box

|

|

Certification

|

ISO9001:2015

|

Advantage:

1.Commitment to Excellence

2.Best Equipment & Highest Skills

3.Accept customization

4.On-time delivery

5.Competitive Prices

6.Outstanding Customer Service

Engineering capabilities include:

1.Parts design.

2.R&D products.

3.Prototype design and production assembly.

4.Reputable design software used for all design work.

5.Hot runner design.

6.Cold runner design.

7.Fast automatice remould design.

8.Mold design with a team of experienced specialists.