Rogers 6006

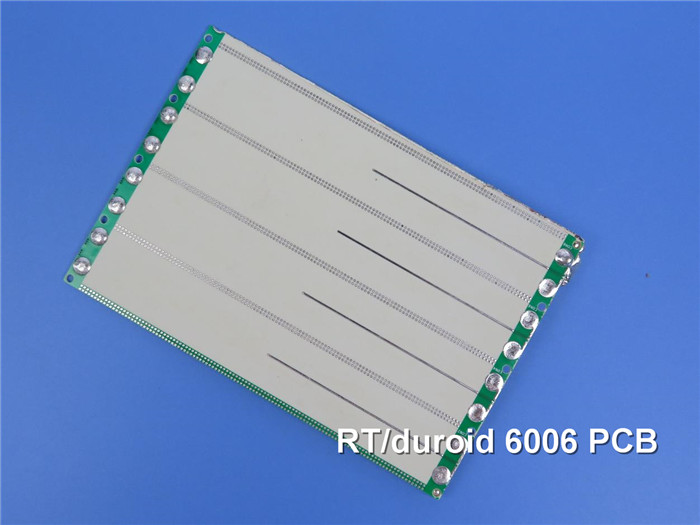

High Frequency PCB on 25mil, 50mil and 75mil Coating Immersion Gold and Green

Mask for Ground Radar Warning

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

Hi Guys,

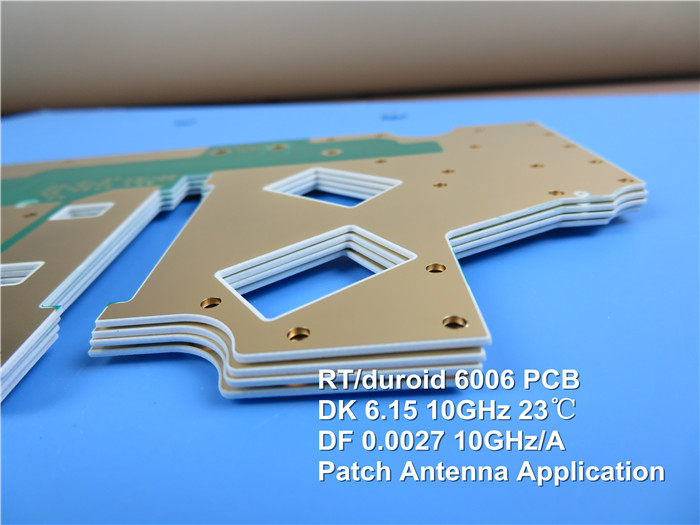

Today we’re going to talk about Rogers 6006

PCB.

Rogers RT/duroid 6006 microwave laminates are

ceramic-PTFE composites which are designed for electronic and microwave circuit

applications requiring a high dielectric constant. RT/duroid 6006 laminate is

available with a dielectric constant value of 6.15.

PCB Capability (RT/duroid 6006):

|

PCB Material:

|

Ceramic-PTFE

composite

|

|

Designator:

|

RT/duroid 6006

|

|

Dielectric

constant:

|

6.15 ±0.15 (process)

|

|

6.45 (design)

|

|

Layer count:

|

1 Layer, 2 Layer

|

|

Copper weight:

|

0.5oz (17 µm),

1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

10mil (0.254mm),

25mil (0.635mm)

|

|

50mil (1.27mm),

75mil (1.90mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black,

Blue, Yellow, Red etc.

|

|

Surface finish:

|

Bare copper,

HASL, ENIG, Immersion Tin, Immersion Silver and OSP.

|

RT/duroid 6006 microwave laminates feature ease

of fabrication and stability in use. This property results in the possibility

of mass production and reducing the cost of goods.

Features and Benefits:

|

1. High

dielectric constant for circuit size reduction

|

|

2. Low loss.

Ideal for operating at X-bank or below

|

|

3. Tight DK and

thickness control for repeatable circuit performance

|

The typical applications are aircraft collision

avoidance systems, ground radar warning systems, patch antennas, satellite

communications systems etc.

Thank you for your reading.

Appendix: Properties of RT/duroid 6006

laminates:

|

RT/duroid

6006 Typical Value

|

|

Property

|

RT/duroid 6006

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric

Constant,εProcess

|

6.15±0.15

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650

2.5.5.5 Clamped stripline

|

|

Dielectric Constant,εDesign

|

6.45

|

Z

|

|

8GHz to 40 GHz

|

Differential

Phase Length Method

|

|

Dissipation Factor,tanδ

|

0.0027

|

Z

|

|

10

GHz/A

|

IPC-TM-650

2.5.5.5

|

|

Thermal Coefficient of ε

|

-410

|

Z

|

ppm/℃

|

-50℃-170℃

|

IPC-TM-650

2.5.5.5

|

|

Volume Resistivity

|

7 x 107

|

|

Mohm.cm

|

A

|

IPC

2.5.17.1

|

|

Surface Resistivity

|

2 x 107

|

|

Mohm

|

A

|

IPC

2.5.17.1

|

|

Tensile Properties

|

ASTM D638 (0.1/min. strain rate)

|

|

Young's Modulus

|

627(91) 517(75)

|

X Y

|

MPa(kpsi)

|

A

|

|

Ultimate Stress

|

20(2.8) 17(2.5)

|

X Y

|

MPa(kpsi)

|

A

|

|

Ultimate Strain

|

12

to 13 4 to 6

|

X Y

|

%

|

A

|

|

Compressive Properties

|

|

ASTM D695 (0.05/min. strain rate)

|

|

Young's Modulus

|

1069

(115)

|

Z

|

MPa(kpsi)

|

A

|

|

Ultimate Stress

|

54(7.9)

|

Z

|

MPa(kpsi)

|

A

|

|

Ultimate Strain

|

33

|

Z

|

%

|

|

|

Flexural Modulus

|

2634

(382) 1951 (283)

|

X

|

MPa(kpsi)

|

A

|

ASTM D790

|

|

Ultimate Stress

|

38

(5.5)

|

X Y

|

MPa(kpsi)

|

A

|

|

Deformation under load

|

0.33 2.1

|

Z Z

|

%

|

24hr/50℃/7MPa 24hr/150℃/7MPa

|

ASTM

D261

|

|

Moisture Absorption

|

0.05

|

|

%

|

D48/50℃0.050"(1.27mm) thick

|

IPC-TM-650

2.6.2.1

|

|

Thermal Conductivity

|

0.49

|

|

W/m/k

|

80℃

|

ASTM

C518

|

Coefficient of Thermal Expansion

|

47

34

117

|

X

Y

Z

|

ppm/℃

|

23℃/50% RH

|

IPC-TM-650

2.4.41

|

|

Td

|

500

|

|

℃TGA

|

|

ASTM

D3850

|

|

Density

|

2.7

|

|

g/cm3

|

|

ASTM

D792

|

|

Specific Heat

|

0.97(0.231)

|

|

j/g/k

(BTU/ib/OF)

|

|

Calculated

|

|

Copper Peel

|

14.3 (2.5)

|

|

pli (N/mm)

|

after solder float

|

IPC-TM-650

2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL

94

|

|

Lead-free Process Compatible

|

Yes

|

|

|

|

|

MANUFACTURING PROCESS:

BICHNEG PCB WORKSHOP:

BICHNEG PCB CERTIFICATION:

BICHENG PCB MAIN COURIERS: