Rogers

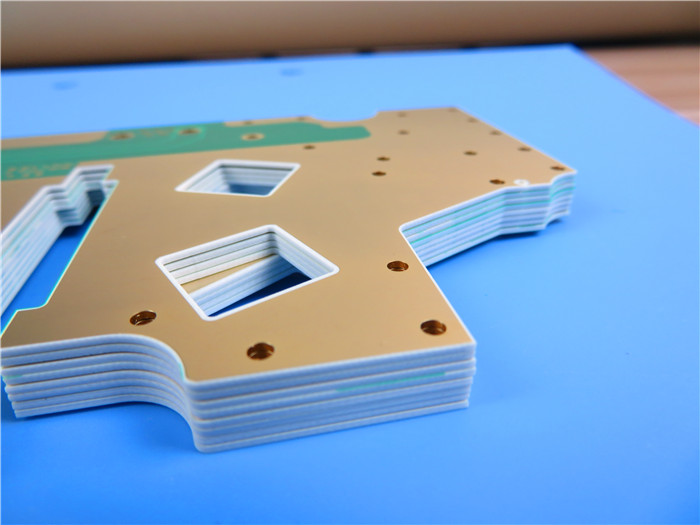

TMM6 Microwave Printed Circuit Board 20mil 50mil 75mil DK6.0 RF PCB With

Immersion Gold

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

General

Description:

Rogers'

TMM6 thermoset microwave laminates are ceramic, hydrocarbon, thermoset polymer

composites designed for high PTH reliability stripline and microstrip

applications. It has the dielectric constant of 6.0 and dissipation factor of

0.0023.

Its

isotropic coefficients of thermal expansion is very closely matched to copper

which results in production of high reliability plated through holes, and low

etch shrinkage values. Furthermore, the thermal conductivity of TMM6 is

approximately twice that of traditional PTFE/ceramic laminates, facilitating

heat removal.

Since

TMM6 is based on thermoset resins, and do not soften when heated. So wire

bonding of component leads to circuit traces can be performed without concerns

of pad lifting or substrate deformation.

Typical

Applications

1.

Chip testers

2.

Dielectric polarizers and lenses

3.

Filters and coupler

4.

Global Positioning Systems Antennas

5.

Patch Antennas

6.

Power amplifiers and combiners

7.

RF and microwave circuitry

8.

Satellite communication systems

Our

PCB Capability(TMM6)

|

PCB

Material:

|

Ceramic,

Hydrocarbon, Thermoset Polymer Composites

|

|

Designation:

|

TMM6

|

|

Dielectric constant:

|

6

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

15mil (0.381mm), 20mil (0.508mm), 25mil

(0.635mm), 30mil(0.762mm), 50mil (1.27mm), 60mil (1.524mm), 75mil(1.905mm),

100mil (2.54mm), 125mil (3.175mm),

150mil (3.81mm), 200mil (5.08mm), 250mil (6.35mm), 275mil (6.985mm),

300mil (7.62mm), 500mil (12.7mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare

copper, HASL, ENIG, OSP, Immersion tin, Immersion silver, Pure gold plated

etc..

|

Why

Choose Us?

1.ISO9001,

ISO14001, IATF16949, ISO13485, UL Certified;

2.More

than 18+ years’ high frequency PCB experience;

3.Small

quantity order is available, no MOQ required;

4.We’re

a Team of passion, discipline, responsibility and honesty;

5.Delivery

on time: >98%, Customer complaint rate: <1%

6.16000㎡workshop, 30000㎡output a month and 8000

types of PCB's a month;

7.Powerful

PCB capabilities support your research and development, sales and marketing;

8.IPC

Class 2 / IPC Class 3

Typical

Value of TMM6

|

Property

|

TMM6

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

6.0±0.08

|

Z

|

|

10 GHz

|

IPC-TM-650

2.5.5.5

|

|

Dielectric Constant,εDesign

|

6.3

|

-

|

-

|

8GHz to 40 GHz

|

Differential

Phase Length Method

|

|

Dissipation Factor (process)

|

0.0023

|

Z

|

-

|

10

GHz

|

IPC-TM-650

2.5.5.5

|

|

Thermal Coefficient of dielectric constant

|

-11

|

-

|

ppm/°K

|

-55℃-125℃

|

IPC-TM-650

2.5.5.5

|

|

Insulation Resistance

|

>2000

|

-

|

Gohm

|

C/96/60/95

|

ASTM

D257

|

|

Volume Resistivity

|

2 x 10^8

|

-

|

Mohm.cm

|

-

|

ASTM

D257

|

|

Surface Resistivity

|

1 x 10^9

|

-

|

Mohm

|

-

|

ASTM

D257

|

|

Electrical

Strength(dielectric strength)

|

362

|

Z

|

V/mil

|

-

|

IPC-TM-650

method 2.5.6.2

|

|

Thermal Properties

|

|

Decompositioin Temperature(Td)

|

425

|

425

|

℃TGA

|

-

|

ASTM D3850

|

|

Coefficient of Thermal Expansion - x

|

18

|

X

|

ppm/K

|

0 to 140℃

|

ASTM E 831

IPC-TM-650, 2.4.41

|

|

Coefficient of Thermal Expansion - Y

|

18

|

Y

|

ppm/K

|

0

to 140℃

|

ASTM

E 831 IPC-TM-650, 2.4.41

|

|

Coefficient of Thermal Expansion - Z

|

26

|

Z

|

ppm/K

|

0

to 140℃

|

ASTM

E 831 IPC-TM-650, 2.4.41

|

|

Thermal Conductivity

|

0.72

|

Z

|

W/m/K

|

80℃

|

ASTM

C518

|

|

Mechanical Properties

|

|

Copper Peel Strength after Thermal Stress

|

5.7 (1.0)

|

X,Y

|

lb/inch (N/mm)

|

after solder float 1 oz. EDC

|

IPC-TM-650

Method 2.4.8

|

|

Flexural Strength (MD/CMD)

|

15.02

|

X,Y

|

kpsi

|

A

|

ASTM

D790

|

|

Flexural Modulus (MD/CMD)

|

1.75

|

X,Y

|

Mpsi

|

A

|

ASTM

D790

|

|

Physical Properties

|

|

Moisture Absorption (2X2)

|

1.27mm

(0.050")

|

0.06

|

-

|

%

|

D/24/23

|

ASTM D570

|

|

3.18mm (0.125")

|

0.2

|

|

Specific Gravity

|

2.37

|

-

|

-

|

A

|

ASTM

D792

|

|

Specific Heat Capacity

|

0.78

|

-

|

J/g/K

|

A

|

Calculated

|

|

Lead-Free Process Compatible

|

YES

|

-

|

-

|

-

|

-

|

MANUFACTURING PROCESS:

BICHNEG PCB WORKSHOP:

BICHNEG PCB CERTIFICATION:

BICHENG PCB MAIN COURIERS: