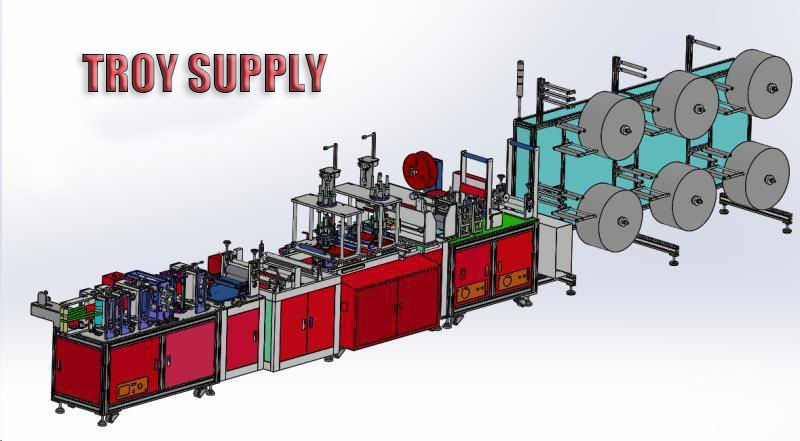

Auto-Production Line

for N95 Face Mask

One. Equipment

introduction:

This

production line realizes the fully automated production of N95 masks, which

mainly includes coil feeding, folding and pressing.

Closing,

nose bridge tendon feeding, mask forming, mask cutting, earband feeding and

welding, logo printing

Brushing,

blanking of finished products, etc., complete the entire production process

from the raw material of the coil to the finished mask.

The

produced masks are comfortable to wear, no pressure, suitable for human face

shape, filter effect up to N95 standard.

Two. Equipment

characteristics:

Using

first-line brand ultrasonic welding machine, welding quality is good, durable;

Modular,

user-friendly design and convenient maintenance;

When

the equipment is abnormal or the material is cut off, it will automatically

stop the alarm and intelligently prompt the abnormal handling operation.

Three. Main

technical parameters of equipment

Equipment

main dimensions 9817mm * 1498mm * 2139mm

Working

power 3P-380V, AC ± 5%, 50HZ

Equipment

power about 15.5KW

Compressed

air 0.5-0.8Mpa

Working

temperature: 0-40 ℃

Humidity:

5-38% HR

Use

environment: No flammable gas or corrosive gas

No

dust (not less than 100,000)

Production

efficiency 40-50 pieces / minute

Folding

symmetry soil 2mm

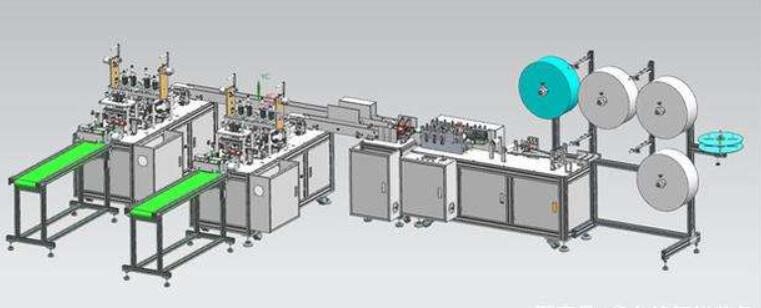

Equipment for Disposable

medical mask

Equipment

Overview:

1.1

This machine is mainly used for the automatic forming of flat masks: the whole

roll of fabric is driven by rollers after unwinding, and the fabric is

automatically folded and hemmed; the entire length of the bridge is pulled and

unrolled. Ultrasonic welding to the seal, then ultrasonic side sealing, cutting

and shaping with a cutter; conveying the mask to the two mask ear band welding

stations through an assembly line, and finally forming the mask by ultrasonic

welding; when the mask is made, The pipeline is transported to the flat belt

line for collection.

1.2

Equipment diagram (This picture is for reference only, the equipment is subject

to the actual product)

1.3

Equipment installation and configuration requirements

(1)

Equipment size: 6500mm (L) × 4500mm (W) × 1900mm (H);

(2)

Appearance color: international standard titanium warm gray 1C, unless

otherwise specified, follow this standard;

(3)

Equipment weight: ≤5000kg, ground load ≤500KG / m2;

(4)

Working power: equipment 220VAC ± 5 ﹪, 50HZ, rated power

of about 9KW; (5) Compressed air: 0.5 ~ 0.7 MPa, using

flow rate of about 300L / min;

(6)

Operating environment: temperature 10 ~ 35 ℃, humidity

5-35% HR, no flammable and corrosive gas, no dust (cleanness no less than

100,000)

The main

components of the equipment

1

filter cloth / filter cotton / absorbent layer unwinding mechanism 4 sets Max4

sets

2

Nose bridge strip unwinding mechanism 1 set

3

nose bridge straightening mechanism 1 set width 3-7mm

4

Nose bridge driving and cutting mechanism 1 set Width 3-7mm

5

fabric hemming mechanism 1 set

6

roll welding edge sealing mechanism 1 set bilateral

7

cloth drive mechanism 2 sets

8

cloth fan folding mechanism 2 sets

9

roll welding side seam mechanism 1 set

10

roll-sealing mechanisms 1 set

11

transfer lines 3

12

shunting mechanism 2 sets

13

ear band welding machine set 2

14

unloading lines 2

15

operating systems 1 set

16

operation panel 1 set

The

equipment can adapt to incoming materials and product specifications

3.1

Applicable incoming specifications:

Cloth 3 axis 170mm ~ 200 Φ600 Φ76.2 Max 15kg

Nose

Bridge strip 1 axis 3-7mm Φ400 Φ76.2 Max 25kg

Ear

band 4 bags 3mm

3.3

Production Specifications:

Standard

type: 175 * 95mm

Equipment

technical parameters:

4.1

Equipment production capacity:

(1)

Production efficiency: 100-110ppm;

(2)

Qualification rate of equipment production: 99% (except that the incoming

materials do not meet the requirements or the employees' improper operation is

excluded)

(3)

Equipment failure rate: 2% (refers to the failure caused by the equipment

itself)

General

equipment configuration and standard requirements

5.1

Configuration list of main components

No.

Item Brand Remark

1-cylinder

SMC / AirTAC

2

Solenoid valve SMC / Yade

3

Servo motor

4

PLC Mitsubishi / Sunjet

5

bearing NSK / Japan, Sanyi / Korea

6-track

STAF, PMI, CPC / Taiwan

7

Fiber, Amplifier Omron, Keyence, Panasonic / Japan

8

touch screen Weiluntong / Kunluntong state

9

Relay Omron / Izumi

10

button dual

5.2

List of standard parts, wearing parts and random spare parts

No.

Name Specification Quantity Remarks

1

Toolbox-1 set of debugging tools