Taconic

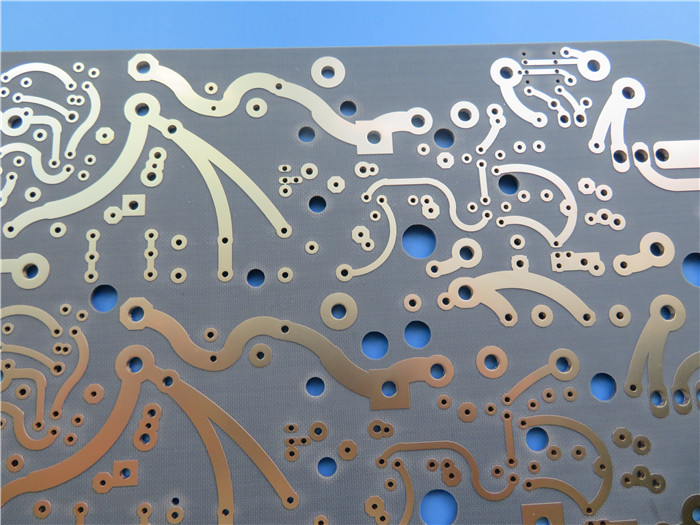

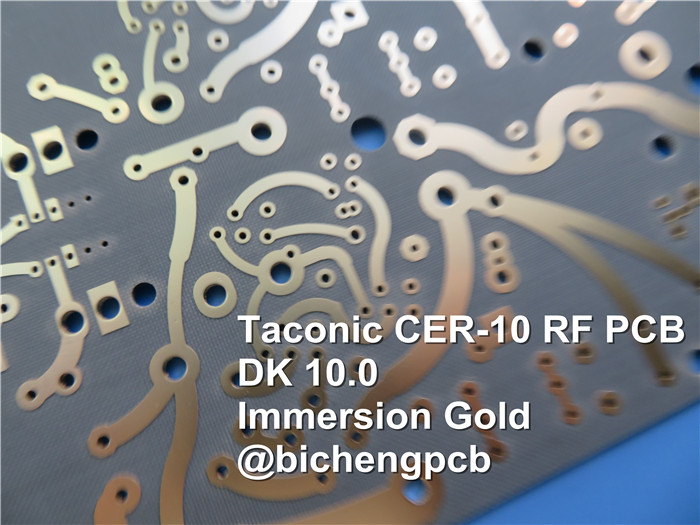

CER-10 RF Printed Circuit Board 2-Layer CER-10 62mil 1.58mm PCB with Immersion

Gold

Its proprietary composition

results in low moisture absorption and uniform electrical properties.

Benefits:

Exceptional

Interlaminar Bond

Low

moisture absorption

Enhanced

dimensonal stability

Low

Z-Axis expansion

Stable

DK over frequency

Increased

flexural strength

Circuit

board miniturization

Applications:

Power

amplifiers

Filters

and couplers

Passive

components

CER-10’s

woven glass reinforcement ensures excellent dimensional stability and enhances

flexural strength. This DK-10 laminate exhibits low Z-axis expansion (CTE 46

ppm/°C), allowing for plated-through-hole reliability in extreme thermal

environments.

CER-10

laminates exhibit flammability of V-0 and are tested in accordance with IPC-TM

650. A certificate of conformance containing lot-specific data accompanies each

shipment.

Our

PCB Capability (CER-10):

|

PCB

Material:

|

Organic-ceramic

Laminate based on Woven Glass Reinforcement.

|

|

Designation:

|

CER-10

|

|

Dielectric constant:

|

10

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

25mil

(0.635mm), 30mil(0.762mm), 47mil(1.194mm), 50mil (1.27mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare copper, HASL,

ENIG,Silver, Tin and OSP etc..

|

Typical

Value of CER-10:

|

Property

|

Test Method

|

Unit

|

Value

|

Unit

|

Value

|

|

Dielectric

Constant (Nominal)

|

IPC-TM-650 2.5.5.6

|

|

10

|

|

10

|

|

Dissipation

Factor 10 GHz

|

IPC-TM-650 2.5.5.5.1

|

|

0.0035

|

|

0.0035

|

|

Moisture

Absorption

|

IPC-TM-650 2.6.2.1

|

%

|

0.02

|

%

|

0.02

|

|

Dielectric

Breakdown

|

IPC-TM-650 2.5.6

|

kV

|

44

|

kV

|

44

|

|

Volume

Resistivity

|

IPC-TM-650 2.5.17.1

|

Mohm/cm

|

2.1

x 108

|

Mohm/cm

|

2.1

x 108

|

|

Surface

Resistivity

|

IPC-TM-650 2.5.17.1

|

Mohm

|

1.1

x 109

|

Mohm

|

1.1

x 109

|

|

Arc

Resistance

|

IPC-TM-650 2.5.1

|

Seconds

|

>180

|

Seconds

|

>180

|

|

Flexural

Strength (MD)

|

ASTM D 790

|

psi

|

16500

|

N/mm2

|

114

|

|

Flexural

Strength (CD)

|

ASTM D 790

|

psi

|

15500

|

N/mm2

|

107

|

|

Tensile

Strength (MD)

|

ASTM D 638

|

psi

|

7700

|

N/mm2

|

53

|

|

Tensile

Strength (CD)

|

ASTM D 3039

|

psi

|

6700

|

N/mm2

|

46

|

|

Peel Strength

(1 oz. ED)

|

IPC-TM-650 2.4.8

|

lbs/linear inch

|

9

|

N/mm

|

1.61

|

|

Dimensional

Stability (MD)

|

IPC-TM-650 2.4.39

|

in/in

|

-0.0002

|

mm/mm

|

-0.0002

|

|

Dimensional

Stability (CD)

|

IPC-TM-650 2.4.39

|

in/in

|

-0.0003

|

mm/mm

|

-0.0003

|

|

Density

(Specific Gravity)

|

|

g/cm3

|

3.05

|

g/cm3

|

3.05

|

|

Thermal

Conductivity

|

ASTM F 433

|

W/m/K

|

0.63

|

W/m/K

|

0.63

|

|

CTE (x-y)

|

ASTM D 3386 (TMA)

|

ppm/℃

|

13-15

|

ppm/℃

|

13-15

|

|

CTE (z)

|

ASTM D 3386 (TMA)

|

ppm/℃

|

46

|

ppm/℃

|

46

|

|

Outgassing

(%TML)

|

ASTM E 595

|

%

|

0.02

|

%

|

0.02

|

|

Outgassing

(%CVCM)

|

ASTM E 595

|

%

|

0.01

|

%

|

0.01

|

|

Outgassing

(%WVR)

|

ASTM E 595

|

%

|

0.01

|

%

|

0.01

|

|

Flammability

Rating

|

UL 94

|

|

V-0

|

|

V-0

|

BICEHNG PCB MANUFACTURING PROCESS:

BICHENG TEAM PRACTICE:

BICHENG PCB EQUIPMENT:

BICHENG PCB CERTIFICATE: